In fluid systems, valves are the core of control. Spring and swing check valves stand out for their unique ability to direct flow and prevent failures. Check valve suppliers recommend these valves for their robustness and ideal setup positions, which are crucial to keeping your system sound. Let us delve into a side-by-side review, maintaining efficiency and practical use in mind, as we unpack the benefits and roles of spring versus swing valves.

Understanding Check Valves: Spring vs. Swing

Check valves are vital for one-way flow in pipes, safeguarding against reverse currents that can cause trouble. Before choosing between spring and swing valves, let us clarify their roles.

Swing valves let flow through with a flap that lifts and falls back to block the wrong-way flow. Their closing ability relies on the liquid's push and gravity's pull.

Operational Mechanics of Check Valves

Knowing how check valves work is vital in fluid control. Both spring and swing types are key for one-way flow and stopping reverse currents. But what's the difference in how they work?

Swing valves have a flap that lifts to let flow through and falls to stop when pressure drops. Spring valves, though, use a spring to shut fast, beating backflow.

The spring tension is vital in these valves. It is the least push needed to open up. With enough push, the valve lets flow through. When the push falls, the spring snaps it shut fast, reacting quickly to flow shifts.

Their working methods significantly affect their performance. Swing valves often face water hammer, a sudden stop in flow that can break a system. By design, spring valves cut the risk of water hammer by shutting before the slam can hit.

Ponder these points as you plan installs and picks for your fluid control needs.

Mechanism of Swing Check Valves Explained

Swing valves are essential in your systems. They have a flap that moves to let fluid through and blocks backflow by snapping back when flow ends. This valve shuts independently as pressure falls, keeping your setup safe without hands. As you think about swing valves, note the broader setup choices of spring valves, which we will explore soon.

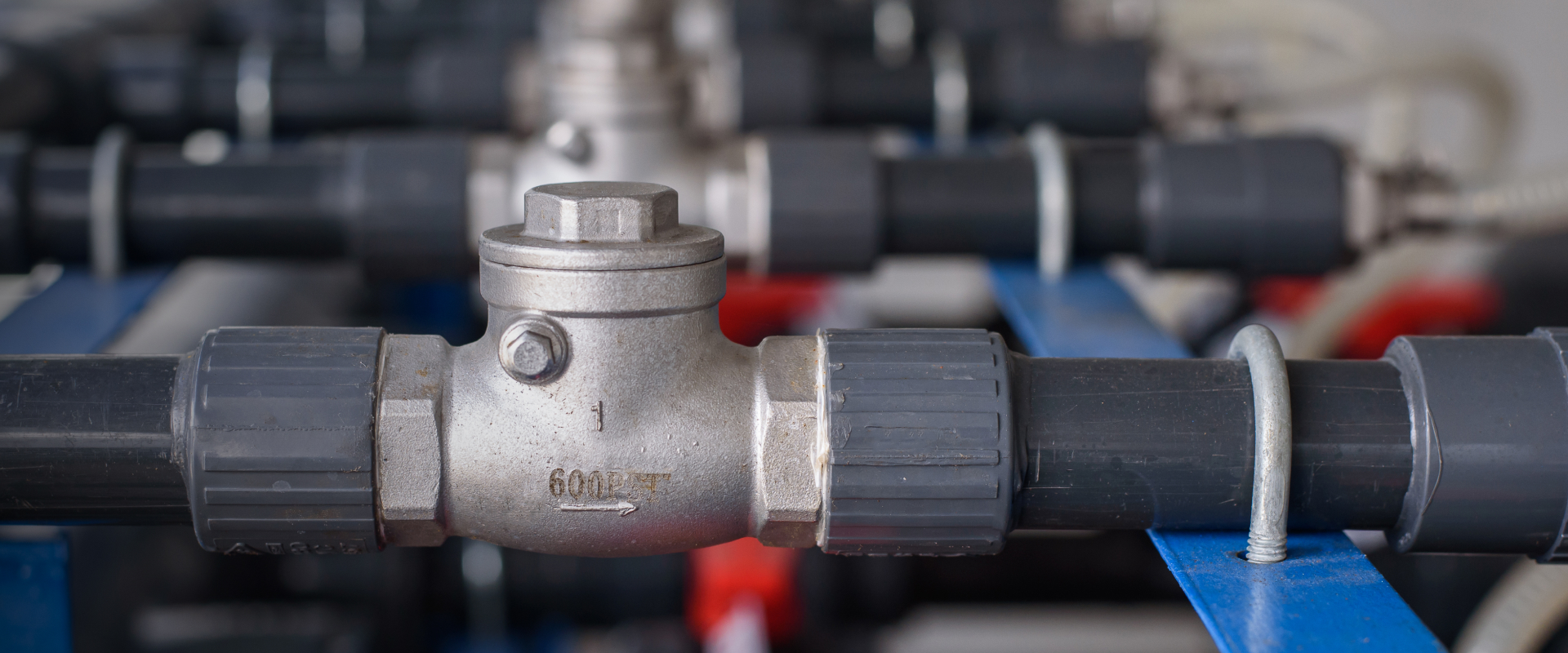

How Spring Check Valves Function

When the force driving the fluid decreases, a spring check valve is designed to close automatically in an industrial environment, preventing backflow. This is crucial for ensuring the safety of your system.

Choosing a spring valve with the appropriate tension that can open with the slightest force is essential. This will ensure that it works as intended.

Spring valves are easy to install, and they can be installed in any direction, making them an excellent choice for complex piping systems. With the proper spring valve selection, your system will operate smoothly and avoid any potential issues.

Check Valve Installation Orientation and Considerations

For check valve setup, the way they face is key and impacts how they work. Swing valves, for example, need a particular setup due to their flap, which gravity helps close. This limits their use to specific flow ways, which can be challenging when your system needs other setups.

On the flip side, spring valves are more flexible and can work in any direction. This is great in tricky pipe setups where space and ways can be tight. But you must choose the right spring for the flow way to ensure it does its job well.

As you plan valve setup in your fluid systems, weigh these points. Picking the correct valve and way can dodge typical troubles and keep things running well.

Limitations in Swing Check Valve Installation

If you are considering swing valves for your fluid systems, know their setup limits. They fit only in flat flow setups or where the flow goes up, which can shape your system design and work.

The setup of swing valves is not just a choice. It is a must for them to work right. If not, the valve might fail, leading to system woes.

As you pick the correct valve, recall the ease of spring valve setup, which can simplify your system design and configuration. Keep this in mind as you weigh the pros and cons of each valve and consider how your choice could shape your system's long-term work and upkeep.

Installation Flexibility of Spring Check Valves

In fluid systems, the ease of valve setup can make a big difference. Spring valves are particularly useful, as they can fit into any flowway. This is especially handy in complex pipe setups where space is tight.

Choosing the right spring is critical, considering the flow way for optimal performance. A well-selected spring with the required push ensures that the valve operates correctly, regardless of the flow way.

By incorporating these valves into your systems, a well-chosen spring valve can keep things running smoothly and prevent the pressure shocks resulting from an ill-fitting valve.

Water Hammer in Check Valves Causes and Mitigation

A water hammer is a pressure spike from liquid that stops or shifts fast, causing noise, shaking, and even pipe breaks.

Spring valves shut independently, helping stop the pressure wave from slamming the valve, which cuts the hammer effect. Swing valves, though, can worsen the hammer with their flap, which stays open until the pressure wave snaps it shut, sending a shock through your system.

When picking valves, think about water hammer effects. It is part of how your fluid system performs.

In-Depth Look at the Water Hammer Phenomenon

Water hammer happens when liquid stops or shifts fast, sending a pressure wave through pipes. This can cause noise, shaking, and damage. The valve type matters for hammer severity. Swing valves, for instance, can worsen the hammer with a loud snap and system breaks. But spring valves use a spring to shut before the wave hits. This early shut can cut or stop hammer effects, making spring valves a smart pick for systems that could face this issue.

Impact of Check Valves on Water Hammer

In fluid systems, knowing how valves affect water hammer is key. Swing valves can make the hammer worse with their late-shutting flap, adding to pressure spikes. But spring valves, often called silent valves, use a spring to help the stopper shut before the wave can slam, helping stop the pressure jumps off the water hammer.

As you pick the best valve, weigh these work differences, especially in setups where the flow might stop fast. Spring valves are a solid choice for complex systems where flow and pressure change.

Comparative Analysis- Pros and Cons of Check Valves

Picking a check valve for your fluid system means knowing the good and bad of swing and spring valves. They each have their own way of working, setting up, and maintaining and are fundamental for your system's safety and work.

Let us look at the main pros and cons of swing and spring valves:

- Swing valves win on cost and are simple to use.

- They can be picky on how they are set up.

- They can lead to water hammer.

- Spring valves are easy to set up in many ways.

- They can help stop water hammer.

- They tend to cost more than swing valves.

With these points clear, you can make a smart choice that fits your fluid systems needs.

Also Read: Harnessing the Benefits and Overcoming the Challenges of Check Valves

Benefits of Using Swing Check Valves

Swing valves are ideal for saving money. Their large flow space allows smooth flow, making them a preferred option for firefighting gear, where strong flow and reliability are crucial. In addition, they play a vital role in sewage setups, preventing floods and safeguarding public infrastructure.

Swing valves have these clear wins:

- They save money, making them easy on the budget.

- They have a big flow space, keeping the flow smooth.

- They are key where strong flow and trust are non-negotiable.

These wins show why swing valves are chosen for certain uses, like firefighting and sewage.

Key Advantages of Spring Check Valves

Spring valves have advantages like easy setup in any flow direction and cutting water hammer risk, which is critical for keeping your system sound. They also stand up to big temperature changes and work well in all sorts of conditions. With quick flow stops and sure seals, they block wrong-way flow well, keeping your gear and work safe.

Spring valves are known for their go-anywhere setup and solid work. Here are their wins

- They fit in any flow way, making setup easy.

- They cut water hammer risk, keeping your system sound.

- They stand up to big temperature changes, working well no matter the weather.

- They stop flow fast and seal sure, blocking wrong way flow.

With these wins, spring valves stand out for maintaining fluid systems safe and working well.

Deciphering Check Valves Strategic Selection for Optimised Performance

Picking the correct valve is vital to keeping your fluid system running smoothly and lasting long. You have looked at how spring and swing valves work and how they fit different setups. Knowing how they help with water hammer lets you make smart picks that match your system's work goals.

Your valve supplier in Russia is the go-to expert for guidance in such matters. Contact them to see how we can help keep your fluid setups at their best. Connect to find the perfect valve choice for your needs.