In sectors like refining and water treatment, the pros and cons of check valves are key to boosting your operations. These devices individually guide fluids, warding off dangers like backflow, which can harm systems and cause contamination.

However, reputed check valve suppliers warn that these devices have limits that must be factored into your plans. This piece will arm you with an understanding of these upsides and downsides, helping you make choices that increase efficiency, protect your setup, and adhere to eco-friendly tech practices.

Exploring the Functionality of Check Valves

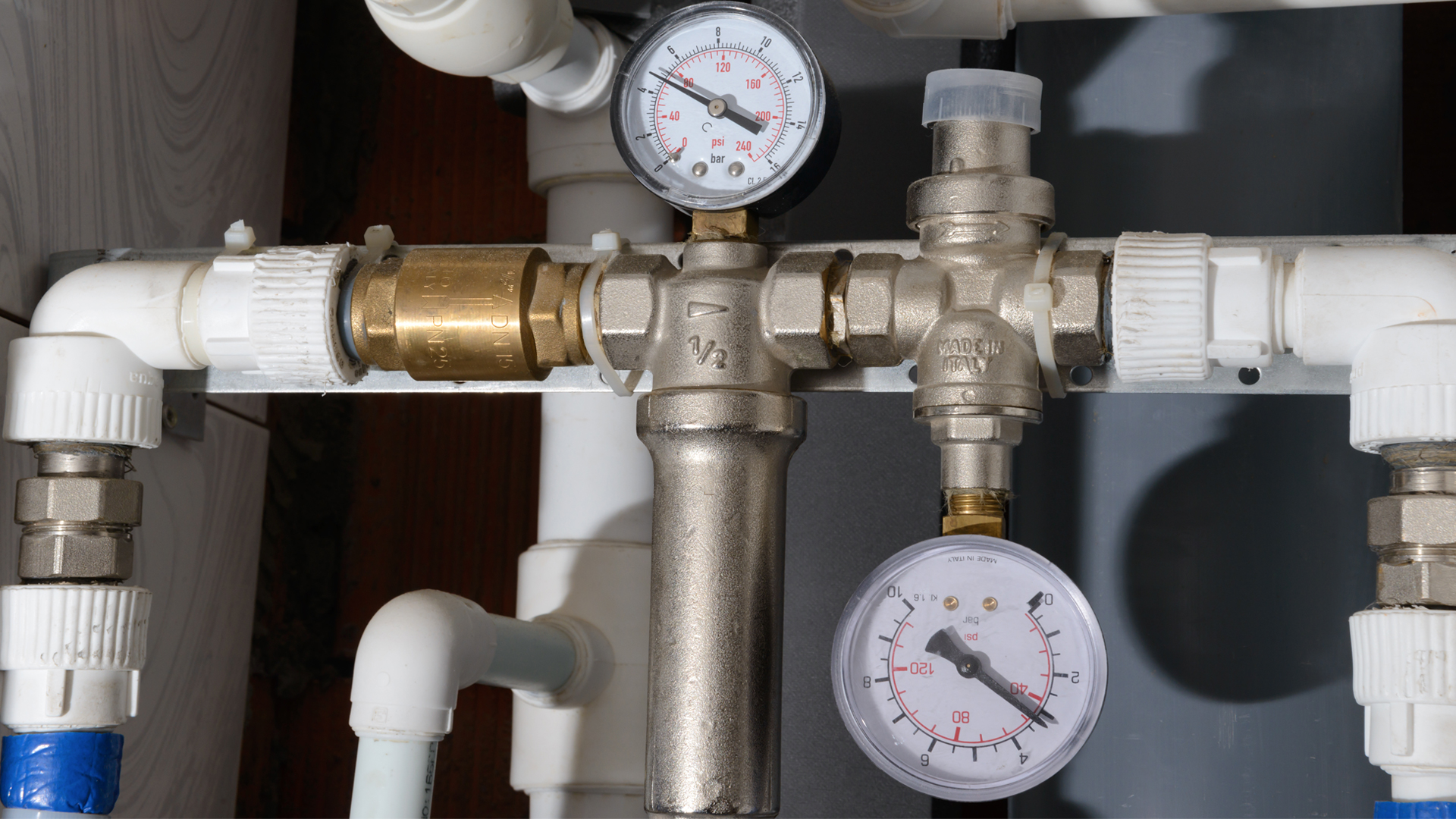

Check valves are an essential component of piping systems. They allow fluids to flow in one direction and prevent them from flowing back. This helps maintain the integrity of the system and prevent potential damage from reverse flow. These valves are typically made from durable materials such as brass or stainless steel, which makes them resilient to harsh environments.

One key advantage of these valves is that they operate independently without requiring external power. They rely on the fluid's pressure difference to function. The main components that make up their structure are the

- Valve body

- Sealing seat

- Flow control disc

- Sspring or hinge (depending on the type of valve and its intended use).

Knowing how check valves work, you can see the perks they bring, like shielding gear from harm and cutting down on upkeep due to their straightforward, efficient design. With this base knowledge, you are set to value the advantages check valves provide in diverse industrial spaces.

Key Advantages of Check Valves in Industry

Before diving into how check valves function, let us spotlight their main industrial benefits:

- They act as a one-way barrier, letting fluids go where they should and blocking any backward flow.

- They have a low fluid flow resistance, making them effective and cost-saving.

- They adapt well to different industry needs, which is another big plus.

With these upsides in mind, It is also key to look at any possible limits of check valves to ensure a well-rounded approach to their use in your systems.

How Check Valves Prevent Backflow and Contamination

Check valves are key in your work, letting fluids go one way and keeping backflow and contamination out. This is crucial in places like water treatment, where they ensure waste does not get back into the clean water, thus guarding public well-being and our surroundings. Check valves play a big part in keeping water setups safe and free from the threats of backflow, all while being low-cost to run and easy to look after.

The Cost Effectiveness and Low Maintenance of Check Valves

Opting for check valves is a wise money move. Their simple build means less upkeep, with fewer parts needing care. This leads to lower wear and longer times between maintenance. Their long life span is proof of their toughness, meaning your investment now will keep giving returns for years. As you ponder these money-saving traits, It is clear that check valves are not just practical but also a smart strategic choice for long-term operational savings.

The Versatility of Check Valves Across Industries

In fields where precision and safety are top priorities, check valves are crucial. They ensure risky chemicals go the right way in chemical plants and refineries, stopping dangerous backflow. In water treatment facilities, they keep clean water safe by blocking contaminated flow.

Even with their many perks, remember that check valves have certain limits, which we will discuss next.

Key Disadvantages of Check Valves in Systems

While check valves are key in many industry processes, they do bring challenges that need understanding:

- Water hammer is a big downside, a situation that can harm systems and cost a lot to fix.

- Clogging is another serious problem, as they can get blocked with stuff like dirt, leading to flow issues.

- The potential costs and operational headaches linked with clogging are worries for any business using check valves for fluid control.

Knowing these downsides is vital for lowering risks and ensuring check valves are used correctly in your work.

Mitigating Water Hammer Risks with Check Valves

To lower water hammer risks in your pipes, picking the right valve size and installing it properly is key. A properly-sized check valve can handle expected flow rates and stop fluid from suddenly stopping, which causes a water hammer.

Smart installation can also minimise risk by smoothly ensuring flow and pressure drop-off. As you focus on these preventive actions, it is also key to monitor other possible problems, like clogging, which can hurt your check valve's effectiveness.

Addressing Clogging Issues in Check Valves

Where fluids have particles like sand, check valves might clog. The types of stuff that can clog them depend on the job. For example, water treatment spots can get organic materials and sediment, while oil and gas spots might have sand or pipe rust. Regular checks and cleanings are vital to stop clogging and keep things running smoothly.

Putting strainers or filters before the check valve can help lower clogging risks. These devices catch debris before it hits the valve, thereby minimising the chances of clogging. Routine inspections and cleaning are key to keeping things working well and making them last longer.

Ensuring your check valve fits your job is a simple but big step toward a dependable setup. Steps like these protect your systems and help keep your work going with no stops.

Sizing and Installation Challenges of Check Valves

Knowing check valves' sizing and installation issues is key to keeping systems efficient and reliable. The right size is crucial to avoid problems from valves that do not fit right, which can mess with how the valve works.

If installation troubles are not fixed, they can lead to less efficient operations and safety worries. With a good grip on the sizing and installation issues, you are ready to look into the mechanics that keep check valves working reliably.

Understanding the Operational Mechanics of Check Valves

Check valves are made to open at a certain low pressure, called the cracking pressure. It is key that your setup can make enough pressure to hit this level for the valve to work. If the pressure is too low, the valve won’t open, stopping the flow. But if it is too high, it could wear out or damage the valve too soon.

How a check valve closes is just as important as how it opens. When flow drops or goes back, the valve has to close to keep backflow out. This usually happens from back pressure, which pushes the valve disc or ball against the seat, sealing it. In some designs, gravity or a spring helps with this closing, ensuring the seal is tight and stopping any backward flow.

It is crucial to install the check valve correctly to ensure its proper functioning. Incorrect installation could lead to severe problems such as pressure buildup and system failure. Most check valves come with an arrow indicating the correct flow direction, which is essential to follow while installing. If the valve is installed backwards, it could stop working and cause harm due to pressure buildup.

Cracking Pressure and Flow Sensitivity in Check Valves

Cracking pressure is the least pressure needed to open a valve, letting the medium flow. It is key because if the setup can't make the needed cracking pressure, the valve won't open, blocking the flow.

Flow sensitivity is about how quickly the valve reacts to flow rate changes. Check valves open and close based on the fluid flow, which is key for dodging system problems like water hammer. To ensure your system can make the needed cracking pressure, look at the valve's build and size and the system’s pressure abilities. Regular checks are also key to stop clogging, affecting cracking pressure and flow sensitivity.

With a solid understanding of these parts, you are ready to ensure your check valves work smoothly.

Closing Mechanisms and Correct Orientation of Check Valves

Your check valves need certain closing mechanisms to keep backflow out. When the flow stops or goes back, the inside disc or ball moves to the seat, sealing it. This is where how you install the valve matters.

A wrongly placed valve can lead to pressure problems and system issues. Set the valve as the maker says to ensure it works right, often shown with an arrow. Paying attention to how you install it is not just about efficiency. It is about keeping your system from failing. As you think about these operational details, you are also considering how choosing materials and valve types will fit your specific jobs.

Exploring Types of Check Valves and Their Industrial Uses

As you aim to improve your industrial systems, knowing the different check valves and their uses is key. Let us look at the common kinds of check valves, how they are used in different industries, and weigh their pros and cons.

- Swing check valves, or tilting disc valves, have a disc that opens when fluid pushes and closes when flow stops. They are handy in setups with solids and are known for quick on/off cycles. Their pro is that they stop backflow well, but a water hammer can hit them if the disc slams shut too fast.

- Ball check valves have a ball that sits on a seat to block backward flow. They are good for setups with particles in the fluid and open when the inlet pressure exceeds the cracking pressure. While they are good at stopping backflow, they can get clogged, which is a downside.

- Diaphragm check valves have a bendy diaphragm that opens with forward flow and seals with backflow. They are good for low-temperature jobs and are liked for their small pressure drop. However, they are limited by how much temperature and pressure the diaphragm material can take.

Each check valve kind has been used well in different industry spots. For example,

- Swing check valves are often in wastewater treatment plants.

- Ball check valves are in chemical processing where fluid purity is key.

- Diaphragm check valves are used in food and drink industries because they meet clean standards.

It is key to balance these benefits with any limits they might have to ensure your choices are well-informed and to use the advantages fully. With the right pick, your check valves can help with the efficiency and safety of your work.

Also Read: Exploring the Applications of Check Valves in Industrial Systems

Material Selection for Check Valve Durability and Compatibility

When picking a check valve for industry jobs, the material you choose is key for ensuring it lasts and fits with the fluid medium. This choice greatly affects the valve’s work and life span.

- Common check valve materials are brass, stainless steel, and PVC.

- Brass valves are good at fighting rust and work well for water, oil, and gas but not for seawater or chlorine setups.

- Stainless steel valves are tough and good at taking high temperatures and rust, making them good for harsh fluids or long times without care.

- PVC valves are cheaper for less tough spots like water management and irrigation, but not for high temps.

Your material pick should be based on things like temperature, pressure, and how corrosive the fluid is. High temps call for stainless steel, while PVC might be good enough for lower temps and less harsh fluids, balancing cost and how well it works.

The right material choice makes the valve work better and last longer, helping your system be efficient and safe. With these points in mind, you can make a smart decision that keeps your check valves working well in any setting.

Weighing the Measures Balancing Check Valve Pros and Cons

You now know the practical perks of check valves for keeping the system wholeness and the issues they can bring. These insights let you balance operational efficiency with safety and being green in your industry tasks.

Connect with your industrial valve supplier in Russia for expert advice. Whether picking the right materials, knowing the water hammer risk, or ensuring the right size and installation, you can confidently pick your check valves with their guidance.

Embracing all these points leads to smarter decisions and, in the end, a strong system work. For more expert advice and custom solutions, reach out and learn more.