Check valves hold a crucial role in fluid flow systems, right? However, the vast array can turn the task of choosing the correct one into a difficult journey. Let's not even touch upon the complexities of troubleshooting. However, this article comes to your rescue. It thoroughly explains check valves, their varied types, and ways to solve common problems. By the end, you'll possess the knowledge to confidently and easily select the suitable check valve for your particular application. So, are you prepared to learn about the world of check valves with the leading check valve supplier in India?

Understanding Check Valves

To understand check valves, you need to grasp their operating principles. This understanding forms the basis for learning about the different types of check valves and solving any possible problems. With this strong base, you can confidently deal with the complexities of check valves. Let's begin.

Different Types of Check Valves

Check valves are essential components in many applications. In this section, you'll explore two specific types: ball check valves and swing check valves. Each type showcases a unique design, operation, and application set. Let's start by enriching our knowledge about these essential tools in fluid dynamics. Our exploration commences with the ball check valve.

Ball Check Valves

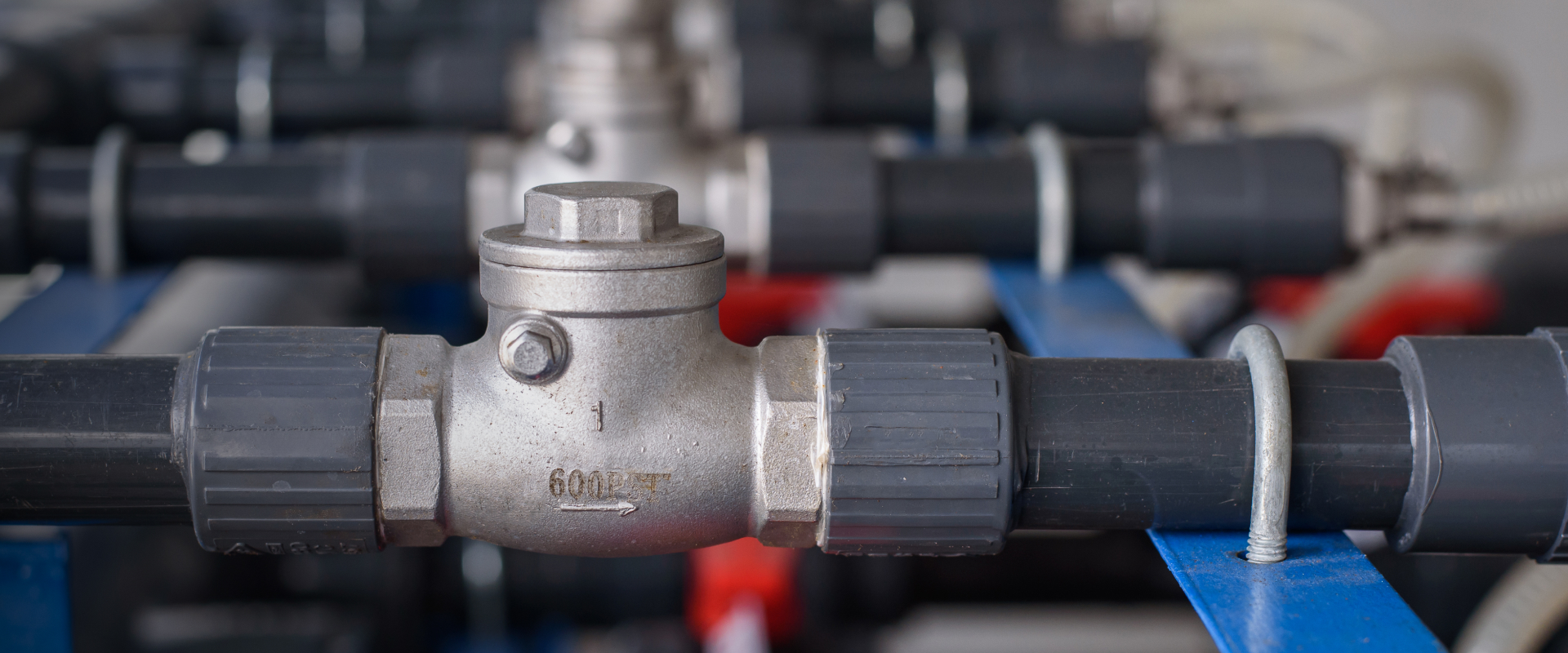

The ball check valve, a key component in fluid flow systems, stops reverse flow in a pipe. The valve contains a spherical ball within the flow path, ensuring flow goes in only one direction. A significant part of the valve, a spring-loaded ball, pushes up against a seat within the valve body. The fluid under pressure pushes the ball against the spring, causing it to rise and allowing the fluid to pass through. However, if the fluid tries to flow in the opposite direction without pressure, the spring force lowers the ball against the seat, closing the flow path.

The plumbing industry often uses check valves in water supply systems like sprinklers, sump pumps, and water heaters to ensure unidirectional flow. These valves' central feature is backflow prevention, which stops potentially contaminated water downstream of the valve from reentering the supply line. For potable water applications, ball check valves made of PVC, brass, or stainless steel are the preferred choice due to their durability.

Injection moulding factories use ball check valves to push plastic forward without backwards slips. Selecting the suitable valve material is vital in applications where the production fluid is not water.

These valves work well on small pumps and in low-head systems. However, they can be harshly impacted by high pressures and dynamics.

There are two types of ball check valves:

- Spring-loaded ball check valves have higher cracking pressure and are used for high-pressure applications.

- Free-floating ball check valves: These are used for low-pressure applications.

Ball check valves are especially useful in pumping stations. Their self-cleaning action during operation maintains valve performance and reduces the need for intervention.

Now that we understand the workings and applications of ball check valves, we shall move on to the swing check valve to make a comprehensive comparison and informed decisions.

Swing Check Valves

Swing check valves, a type of check valve, function with the help of a hinge or a shaft mechanism. The disc, often known as the "swing disc", swings on this hinge or pivot at the top of the valve, determining the fluid flow direction. The hinge mechanism varies from simple hinge pins to dual-plate designs or butterfly-style hinges, subject to the application and flow parameters.

When fluid flows the right way, the pressure pushes the swing disc to open, forming a path for the fluid. But if the fluid attempts to reverse its flow, the swing disc returns to its closed position, sealing against the valve seat. This quick action, supported by gravity and fluid pressure, effectively stops backflow.

Swing check valves are recognised for their low-pressure drop when fully open, reducing energy loss and boosting system efficiency.

Here are some primary features of swing check valves:

- Correct installation demands the flow direction to align with the arrow marked on the valve body. Incorrect installation can result in malfunction and potential damage.

- They find extensive use in petrochemical, pharmaceutical, water treatment, and food processing industries.

- They are suggested for systems needing backflow prevention, like pumping applications or systems with changing upstream pressures.

Swing check valves are available in various designs, including a straight body or a Y-pattern, and come in sizes 2 inches and over.

Another type of swing check valve is the tilted disc check valve. The disc in this valve is hinged radially on one side. When the pressure at the valve inlet port rises, the disc swings open, allowing fluid flow. If backflow happens, the disc returns to its initial position, closing the passage completely. This valve operates without a spring, and the disc's movement depends solely on gravity.

With this knowledge of swing check valves, you're well-prepared to handle any issues that might pop up. In the next section, we'll discuss common issues with check valves and how to troubleshoot them.

Also read: Understanding Check Valves: Components & Their Crucial Role in Flow Control

Troubleshooting Common Check Valve Issues

You may face a few obstacles while maintaining the optimal function of your check valves, which is quite alright because it's a part of the process. Practical solutions exist for common problems with check valves.

AlterValve is a valve supplier that offers a wide range of high-quality industrial valves and parts for various sectors such as power plants, oil and gas, petrochemicals, and more. It sources its products from qualified valve manufacturers and supplies in China, India, and Russia, and ensures that they meet strict quality and safety standards.

Troubleshooting Check Valves

Even the most efficient check valves can face problems that disrupt their operation. Let's examine some of these usual issues and their solutions.

- A stuck valve: This common problem occurs when the valves, which should be fully open, become stuck due to corrosion of the valve parts. But there's no need to panic, you don't have to replace the entire valve. You can correct this problem and make the valve functional again.

- Leakage during installation: This could happen if the O-ring has worn out. Over time, the valve seat seals, which endure the effects of age and friction, can deteriorate, allowing some fluids to slip past and damage the valve. This damage can cause the check valve to fail.

- Interference from loose material: Debris can lodge itself within the valve's opening or exit, causing the valve to remain fully open or closed. This disrupts the regulation of water or gas flow.

- Low fluid pressure: This can happen with different types of check valves, especially ball check valves. A pressure differential is essential for the function of a one-way valve. If the valve isn't working well, low flow could be the cause. This could be due to an overly broad or blocked pipeline.

- Noisy operation: If the valve makes noise during operation, examine the system piping for trapped air. A partly open valve can also create a lot of noise; in this case, replace the ball with a lighter one.

A sudden stop or change in the direction of the fluid can lead to a pressure increase in swing check valves, also known as a water hammer. Since these valves depend on the reversal of fluid flow for quick closure, water hammer is a frequent problem.

Understanding these potential problems and their solutions is vital for effectively correcting check valves. These troubleshooting tips should prepare you to deal with common check valve issues more effectively.

Embracing Check Valve Expertise

For effective selection and troubleshooting, it is crucial to have a deep understanding of each type's design, operation, and application. If you need more personalised insights or assistance, experts from AlterValve, the leading valve suppliers, are always available. As a renowned mechanical engineer once said, "Success is found in the details." So, let's continue to improve our knowledge of check valves, because understanding leads to mastery.