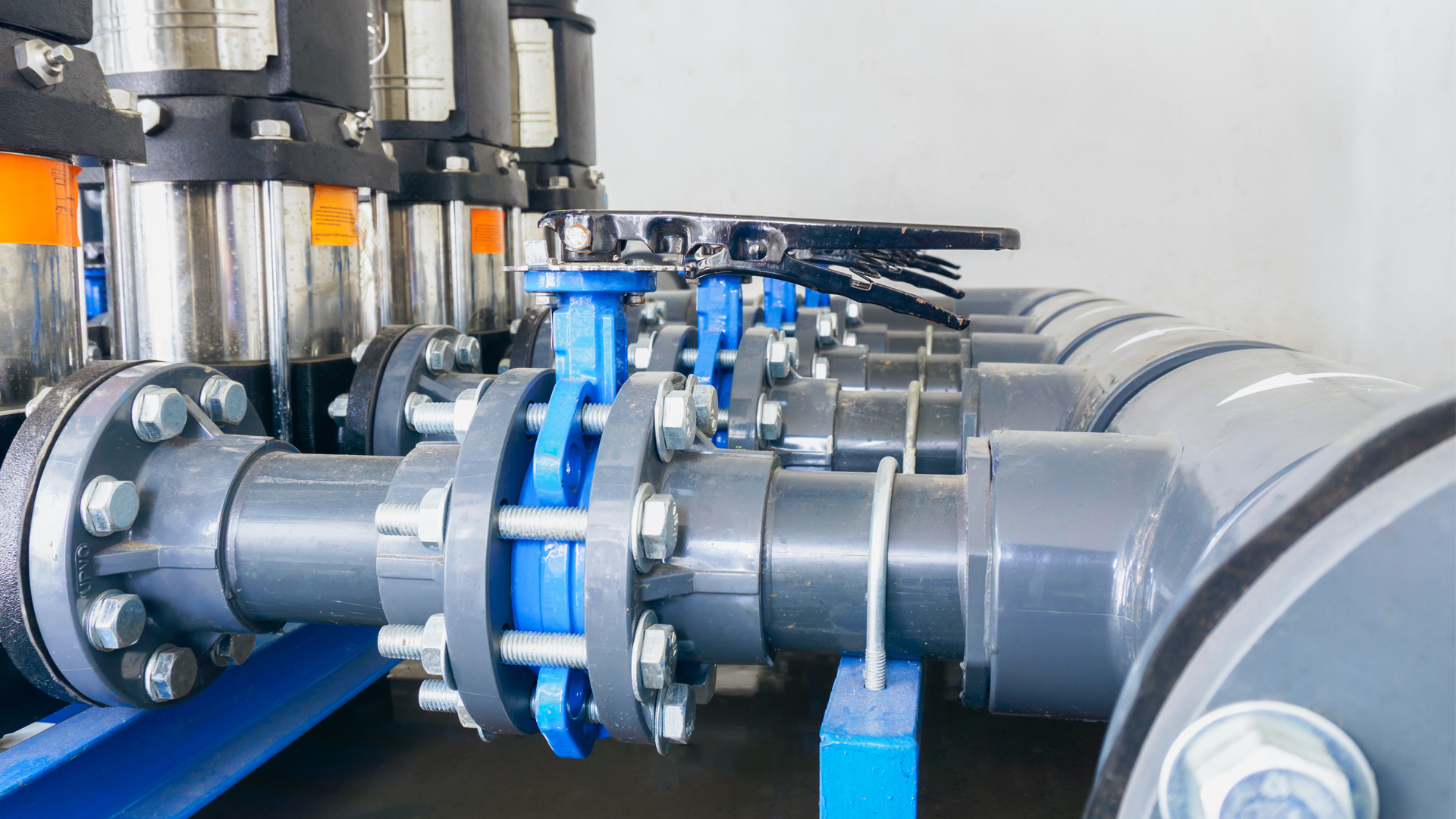

Professionals managing fluid control systems need a solid understanding of butterfly valve parts. These parts work together to control fluid flow precisely. The main elements – body, disc, seat, and stem – are the heart of the valve’s functionality and efficiency. Knowing these parts helps you choose the suitable butterfly valves for your needs. Let us delve into each component and how they each play a part in effectively operating butterfly valves.

Comprehensive Overview of Butterfly Valve Parts

Have you placed an order with your butterfly valve supplier for various valves? Your knowledge of butterfly valve parts will help you decide what to invest in.

The key parts of butterfly valves and their roles include:

- The body, which is the core structure, is made from materials like carbon steel to titanium.

- The disc, which manages fluid flow, can be concentric or eccentric in design.

- The seat seals tightly with the disc and comes in elastomers and polymers.

- The stem, which links the disc to the actuator, needs careful selection for direct fluid contact.

Remember the crucial part the valve body plays, affecting its life span and how well it fits specific uses.

Valve Body Types and Their Functions in Butterfly Valves

In the market for butterfly valves? Know the different body types and their uses. These valves are simple and effective for fluid flow control. Let us look at two main body types: lug and wafer.

Lug bodies have external threads for bolt installation that match the pipe flanges. They are great for some uses, like dead-end service, which lets you remove downstream piping without system issues. This makes maintenance simpler.

Pick a lug body valve based on how well it fits your piping system. These valves support the system’s weight, making them strong for various uses. Often, they are chosen when one side of the system might need disconnecting or service without affecting the other side.

Wafer bodies are cost-effective and simple to install. They fit between two pipe flanges, with bolts holding the valve body. The wafer setup is simpler and cheaper than the lug.

The valve body’s material is key to its performance. Carbon steel is common for general use, while stainless steel, nickel alloy, and titanium are better for tough environments due to their corrosion resistance. The material choice affects the valve's life span and suitability for specific uses.

As you pick the right valve body, think about how the disc interacts with it. The disc is the part that opens and closes to manage fluid flow. Its connection with the valve body is vital for good flow control.

Disc Component- Regulating Flow in Butterfly Valves

The disc is vital for managing fluid flow in a butterfly valve. Its position controls the flow rate and ensures a solid shut-off when closed. Butterfly valves have different disc designs, affecting their performance.

Concentric designs with a stem through the disc’s centre are good for simple on/off tasks in low-pressure areas. Eccentric, or offset discs, with a stem-off centre, reduce wear on the disc and seat, helping the valve last longer.

The disc's angle impacts flow traits and sealing. Eccentric designs have the disc move away from the seat with little friction, which lowers torque needs and smooths operation. This design also helps with a tighter seal, which is important for leak prevention.

Your butterfly valve performance relies on the discs' design and angle, managing the flow and ensuring dependability. The disc and seat interaction is crucial for the valve's success, making it a reliable option for flow management.

Seat Mechanism- Ensuring a Tight Seal in Butterfly Valves

The seat in your butterfly valve ensures a tight seal to stop leaks and keep the system intact. Made from tough materials like elastomers or polymers, such as PTFE or RTFE, the seat must match the media it faces, whether that is corrosive stuff or high heat.

A solid seal often comes from an interference fit design, with pressure between the seat and the disc edge. Line-energised designs use pipeline pressure to improve the fit for better sealing under changing pressures. The seat design is central to the valve's performance, affecting its ability to control fluid flow and maintain system pressure.

With the seat's role in a secure system, the stem’s part in the valve’s function becomes just as important.

Stem Design Connecting and Operating Butterfly Valves

The stem is a core part of a butterfly valve, connecting the disc to the actuator. The stem design is a big factor in the valve's efficient performance.

Wetted and non-wetted stem designs fit different media exposures. Wetted stems, touching the process fluid, need materials that can resist corrosion or erosion, while non-wetted stems, away from the fluid, can use a wider range of materials. The right design depends on the media type, with non-wetted stems being better for harsh fluids to help the valve last longer.

Stem material is important, with stainless steel often used for its toughness and corrosion resistance. Materials like Hastelloy or titanium are chosen for their top-notch chemical resistance in very corrosive settings.

When you look at stem design and material options, think about how these choices affect the butterfly valve's overall performance and life span. The right pick can hugely impact the valve's efficiency and longevity, ensuring it meets your specific needs.

Also Read: A Comparative Guide Gate Valves vs Butterfly Valves

Material Selection for Butterfly Valve Components

Choosing materials for butterfly valve parts is important for the valve’s function and life span. Here is a look at some common materials and their typical uses:

- Stainless steel- Great for its corrosion resistance and strength and ideal for tough settings.

- Carbon steel- Less corrosion-resistant but cost-effective for non-corrosive uses.

- Alloys like nickel or titanium- Excellent for extreme conditions.

- Corrosion-resistant materials like aluminium bronze- Ideal for harsh environments to ensure valve durability, especially in seawater, to fight corrosion and biofilm growth.

Knowing these material's traits and uses helps you ensure your butterfly valve works well where you plan to use it.

Manual vs. Automatic Actuation for Butterfly Valves

Choosing between manual and automatic actuation is a big decision. Here is what to know about each type:

- Manual actuation uses hand levers or gearboxes and is simple but can be hard work for big valves or if used a lot.

- Automatic actuation is easier and can be part of automated systems. It includes electric, pneumatic, or hydraulic actuators, each fitting different settings and uses.

The most appropriate actuation method depends on the valve's size and usage. Manual levers are suitable for small, infrequently used valves, whereas automatic actuators are necessary for large or hard-to-reach valves. Your actuation choice should be based on:

- The valve's size.

- How often it is used.

- The conditions it will face.

Exploring the Fine Points of Butterfly Valve Design

As you have seen, each part of a butterfly valve is key to its ability to manage fluid flow smoothly in various industrial uses. With well-made parts like the body, disc, seat, and stem, these valves are important for keeping your systems efficient and safe. Choosing the right materials adds to their strength and fit for the job. Knowing these details is vital for ensuring your valves work well and last. Connect with your valve supplier in Russia to learn more about custom options that fit your operation-specific requirements.