Increasing the life of a globe valve might appear challenging, considering the numerous factors that can influence its durability. However, you don't need to worry. This article will equip you with the necessary understanding. It will clarify the basic aspects of globe valves, highlight the elements affecting their lifespan, and offer practical methods to extend their service life. Furthermore, it will reveal the most appropriate materials for improved durability and how an experienced globe valve supplier can guide you. So, get ready to thoroughly understand globe valves and how to increase their life.

Understanding Globe Valves

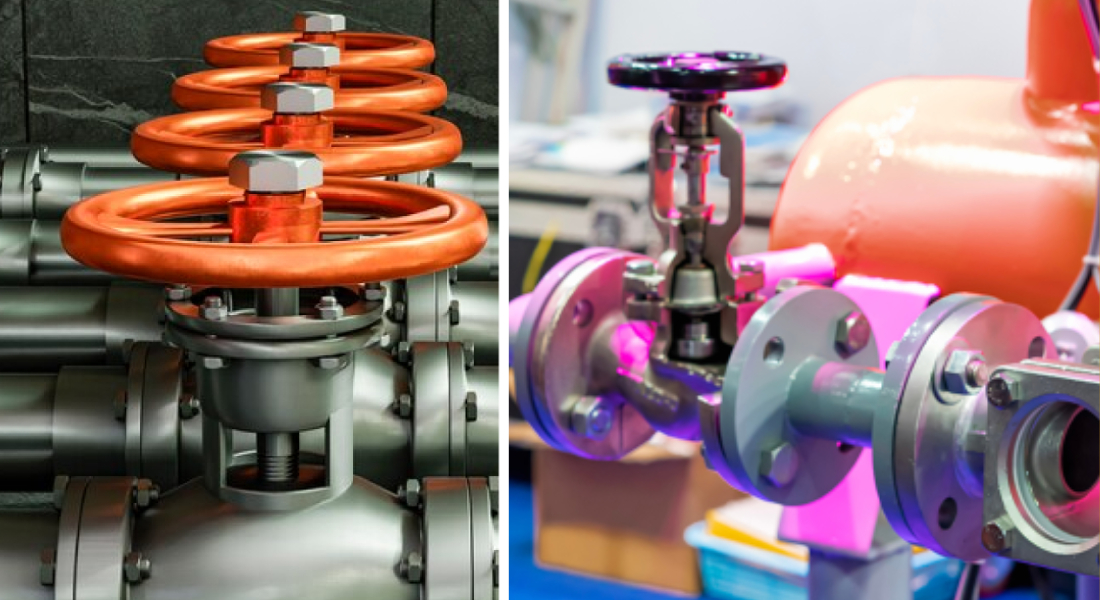

Globe valves hold significant importance in the realm of fluid control systems. Their specific design enables the regulation of fluid flow. The unique structure of these valves allows the discs to move in a straight line, enhancing their efficiency in managing fluid flow. They exhibit versatility by functioning in either completely open or closed positions, giving the flexibility to permit or completely stop media flow.

Here are some distinctive characteristics of globe valves:

- They operate in a single direction, which lessens the pressure on the working parts.

- Because of their external shape, they are widely used in plant pipes.

- They provide versatility in operation, allowing either manual or automatic control.

- Unlike gate valves, they can modulate flow or pressures and completely halt the flow.

- They can also function as check or pressure relief valves.

Despite their unique features, globe valves may encounter operational problems. These issues can lead to fluid wastage, reduced valve functionality, and even system damage. Therefore, understanding the factors that can influence the lifespan of a globe valve and how to increase the life of a globe valve is of paramount importance.

Also read: What is the Difference Between a Gate Valve and a Globe Valve?

Factors Affecting the Lifespan of a Globe Valve

The lifespan of your globe valve depends mainly on two critical elements: the material used and the operating conditions. Understanding these aspects can help you make informed decisions to extend the life of your globe valve. Now, let's examine these factors more closely.

Material Type

Have you ever considered the significant role the material of your globe valve plays in its lifespan? Corrosion, a common issue, arises when the material of the valve clashes with the system fluid. Even the valve disc, a crucial part of the valve, doesn't escape from corrosive testing fluids. Let's now examine the impact of operating conditions on the longevity of your globe valve.

Operating Conditions

A globe valve's lifespan depends greatly on its operating conditions. For example, when high-temperature steam flows through the valve, it creates a considerable temperature difference within the valve. As time progresses, the globe valve may become rigid, and its ability to maintain pressure could diminish. This deterioration can be seen through leakages, signalling potential problems with the valve seat or plug. Managing these operating conditions effectively is crucial to prolonging the life of your globe valve. Now, we will discuss some practical ways to extend the life of your globe valve.

Techniques to Increase the Life of Globe Valve

The lifespan of a globe valve doesn't require complex knowledge. It boils down to two fundamental aspects: consistent maintenance and proper installation. Master these, and your globe valve will function effectively for an extended period. Now, we will discuss these methods in detail.

Regular Maintenance

To extend the life of your globe valve, follow these steps during your regular maintenance checks:

- Set a regular inspection schedule for your valve systems.

- Monitor the stem's motion closely. Exposure to the environment might cause it to accumulate dirt or grit. Regular lubrication of the stem ensures the valve operates smoothly.

- During these inspections, look for signs of wear on the external hardware, such as nuts, washers, and bolts. Replace promptly if you detect wear, and tighten them adequately.

The frequency of these inspections might vary based on several factors. These include the type of fluid the valve regulates, the pressure on the valve, and how frequently the valve is used in daily operations.

AlterValve is a valve supplier that offers a wide range of high-quality industrial valves and parts for various sectors such as power plants, oil and gas, petrochemicals, and more. It sources its products from qualified valve manufacturers and supplies in China, India, and Russia, and ensures that they meet strict quality and safety standards.

Proper Installation

Understanding the importance of correct installation is key to prolonging the life of your globe valve. The installation process requires placing the valve vertically on the pipe with the handwheel at the top. This position ensures optimal valve operation. Avoid over-tightening the handwheel, as this could place unnecessary pressure on the gland packing, potentially leading to early damage.

Your globe valve, being unidirectional, holds a crucial role in controlling the flow of the commodity. You can adjust the flow rate to your preferred level by manipulating the handwheel.

Following these simple steps can ensure the optimal performance and increased life of your globe valve.

Having discussed the installation process, let's move on to another crucial aspect that can increase the life of your globe valve - choosing suitable materials.

Choosing the Right Materials for Longevity

The materials you choose greatly affect the lifespan of your globe valve. Your choice should consider the specifics of your operation and the compatibility of the valve material with your fluid system. Here are some important considerations:

- Choosing globe valves that meet your operational requirements and specifications is vital.

- Always incorporate new O-rings and gaskets when you put your valve back together. This ensures a tight seal.

- If necessary, replace the gland packing without a second thought.

Taking these key steps can significantly increase the life of your globe valve.

Conclusion

Enhancing the life of a globe valve might seem complex, but it doesn't have to be. The key lies in understanding the basic features of these valves, recognising the factors that could impact their longevity, and employing effective strategies to strengthen their lifespan. The choice of materials and the conditions under which the valves operate are crucial. Routine maintenance and correct installation are not to be overlooked. This knowledge equips you to make informed decisions and significantly extend the life of your globe valves.

Don't hold back. Seek advice from AlterValve, one of India's best industrial valve suppliers, and start your journey towards long-lasting globe valves. Remember, "Knowledge is power."