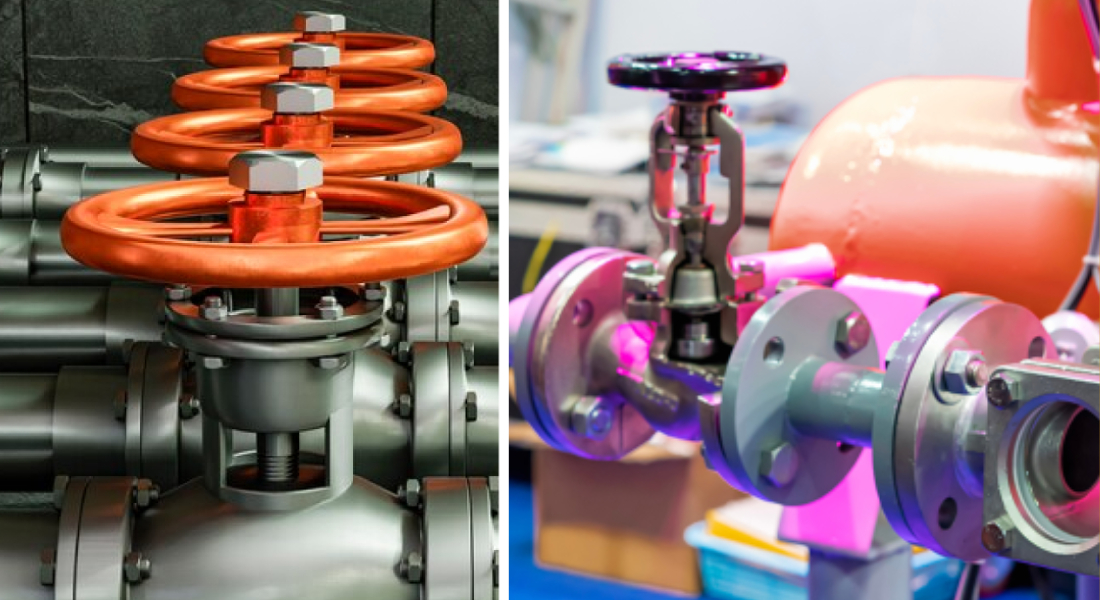

Step into the realm of precision and control in fluid dynamics. Here, globe valves stand as pivotal elements within the industrial valve scene. Their key parts- the body, bonnet, stem, disc, seat, and actuator collaborate seamlessly to manage flow with precision.

For professionals in the industry, familiarity with these parts is key to mastering flow control. Let us enhance your understanding of globe valve components and their critical role in effective flow management.

Globe Valves and Their Importance

Globe valves, known for their round shape, are expertly crafted to manage flow start, stop, and regulation. They play a key role in various industries, excelling in flow control. The valve design lets the disc fully open or close the flow, making it perfect for isolation and throttling tasks.

Globe valve suppliers deliver these devices for various applications- from cooling systems that regulate flow to fuel systems that need a tight shut-off.

These valves have adapted to meet today’s industries' demands. This change shows the industry's dedication to better flow control solutions. Realising their broad use and importance, It is clear that knowing their components is about more than just recognising parts. It is about appreciating their role in precise flow regulation. This leads to an interest in their various designs and types.

Exploring Globe Valve Designs and Types

Let us look into the main globe valve types, each offering specific benefits and uses:

- Tee Pattern Globe Valves- Known for their Z shape, they are great for heavy throttling despite causing more pressure loss.

- Angle Pattern Globe Valves- Their 90-degree angle allows a single flow direction change, reducing pressure loss and fitting for pulsating flows.

- Wye Pattern Globe Valves- With a 45-degree angled seat and stem, they offer a straighter flow path, ideal for long-term throttling and less prone to erosion.

Understanding these designs is vital for choosing the right globe valve for your flow and pressure needs.

Tee Pattern Globe Valves- Design and Applications

Tee Pattern globe valves are your ally in heavy throttling services or when pressure loss is not a major concern. They lead to a higher pressure drop due to the flow path changing twice.

This valve design has the lowest flow coefficient, indicating efficiency in passing fluid. This is especially good for applications needing precise flow control over minimising pressure loss. These valves are commonly found in bypass lines around control valves or systems needing fine flow adjustments.

Despite the increased pressure loss, the Tee Pattern design is sturdy for applications requiring regular and precise throttling. They maintain smooth and efficient operations without the need for frequent maintenance.

In industries where flow regulation is crucial, such as power generation or water treatment, Tee Pattern globe valves are invaluable for their control and reliability, as they keep operations running smoothly without requiring constant upkeep.

Angle Pattern Globe Valves- Unique Flow Dynamics

When managing flow in your systems, angle pattern globe valves are crucial for their distinctive flow dynamics. This valve type changes the flow direction with a 90-degree turn.

This angle change is great for pulsating flows, making the valve a strong choice in industries like chemical processing and HVAC, where precise fluid and temperature control are needed.

Their compactness also means smoother flow transitions, reducing stress like a water hammer. This makes them a strategic pick for systems needing both a valve and an elbow, cutting down on extra fittings.

With the benefits of angle pattern globe valves in mind, it is clear their design is a key part of efficient flow control in various industrial applications.

Wye Pattern Globe Valves- For High-Pressure Applications

The Wye Patter Globe Valve is indispensable in high-pressure systems, where its unique design features a 45-degree angled stem and seat, leading to a straighter flow path when fully open. This design reduces flow resistance, which is perfect for expected high-pressure drops.

The Wye pattern design also helps in long throttling periods, minimising wear and erosion. This is helpful in high-pressure and abrasive fluid operations.

Besides their durability, Wye Pattern Globe Valves are versatile. They are often used in seasonal or startup operations where throttling controls flow rates. Their design makes maintenance easy, such as clearing debris in closed drain lines.

Essential Globe Valve Components and Their Functions

To fully understand globe valves, let us look at each key part:

Body and Bonnet- Ensuring Integrity

The valve body and bonnet form the core of the valve’s integrity, keeping fluids contained and maintaining system pressure.

Different bonnet designs suit various needs and maintenance. Bolted bonnets are common for their simple maintenance. Pressure seal bonnets are better for high-pressure and temperature applications, sealing better as pressure increases.

With the body and bonnet as the foundation for operation, It is important to know how they affect the valve's function and reliability. As you look at the sturdiness of these parts, also consider the disc and seat mechanism's role in precise flow control.

Disc and Seat Mechanism

The disc, attached to a stem, meets the stationary seat when closed, forming a precise seal crucial for stopping the flow. The disc position can be finely adjusted, giving globe valves their reputation for precise flow regulation.

Globe valves have different disc designs, each affecting throttling and sealing. The composition disc design has a hard, non-metallic insert ring on the disc, ensuring a tight closure for steam and hot water systems. The plug disc design is known for its durability and tight seal.

The seat design is just as important. It must endure constant contact with the disc, especially in throttling, where the disc may partially block the seat for a long. A good seat design reduces wear on the disc and seat, reducing maintenance and keeping the valve efficient over time.

Stem and Actuation Systems

Your globe valve’s stem is vital, linking the actuator to the disc and turning your manual or automated commands into action. This link is key to the valve’s function, directly affecting fluid flow. There are two types of actuation:

- Manual options like handwheels or levers are great for simple, direct control.

- Automated systems, like electric, pneumatic, or hydraulic, allow remote control and integration into complex systems, important for precision and safety.

The stem design is central to the valve's responsiveness and maintenance. For example, a non-rising stem design is good for limited space, while a rising stem shows the valve's status. These designs are crucial for ensuring your globe valve works well and meets the demands of your specific uses.

Operational Mechanics of Globe Valves Explained

Globe valves, with their spherical bodies and inner workings, play an important role in regulating flow in different systems. Knowing how they work is crucial for precise flow control.

The main idea behind a globe valve is the linear motion of its disc. As you turn the handwheel or use the actuator, the stem. a rod-like piece. turns this rotation into linear movement. This moves the disc, attached to the stem, to adjust the fluid flow through the valve seat, where the disc sits to seal.

This linear movement is unique to globe valves, letting you adjust flow rates with precision. The design ensures that as the disc moves towards the seat, the space for fluid to pass narrows, allowing for incremental flow changes. This is useful in applications needing close flow or pressure management.

Also, the installation orientation of a globe valve can affect its performance. Normally, globe valves are installed with the stem vertical, so system pressure helps seal when the valve is closed. But for high-temperature services, like steam, the pressure is often above the disc to keep the stem from contracting and possibly lifting the disc off the seat when cooling.

With this knowledge of globe valve operations, you can better evaluate their pros and cons in industrial contexts.

Industrial Pros and Cons of Globe Valve Components

In industrial use, globe valves are chosen for their precise flow control. But, deciding to use them should come from understanding their pros and cons. Globe valves are versatile and offer precise flow regulation, fitting many applications. Yet, they can also cause a higher pressure drop, affecting system efficiency.

When picking globe valves, think about your application's specific needs. For example, in systems where pressure maintenance is less important, the precision control of globe valves may be beneficial. On the other hand, where minimising pressure drop is key, other valve types might be better.

Carefully considering these factors will help you choose the right globe valve, ensuring it meets your industrial needs without affecting performance.

Selecting the Right Globe Valve Components

Here are some key points to remember when choosing globe valve components:

- Make sure materials match the media.

- Pick the right valve design based on flow dynamics and pressure drop.

- Check that the valve follows industry standards.

- Look at valve features that affect performance, like disc design and actuator type.

Also Read: Guide To Maintenance and Troubleshooting of Globe Valves

Technological Advancements in Globe Valve Components

Globe valve actuation has seen great innovation, with new mechanisms offering precise control and better efficiency.

Modern electric, pneumatic, and hydraulic actuators are more responsive and energy efficient. These new designs are compact and integrate well with modern control systems, giving you real-time data and remote operation abilities.

One of the biggest changes in globe valve components is the use of smart technologies. Smart globe valves with sensors and digital communication are becoming standard. These valves can monitor different operation parameters, like pressure, temperature, and flow rate, and adjust them for optimum performance.

IoT (Internet of Things) technology means globe valves can now be part of a connected network, letting you monitor and control valves from a central location. This makes operations more efficient and safer by giving early warnings of potential problems.

These advancements are overcoming traditional globe valve limitations. For example, new designs that lower flow resistance minimise the issue of high-pressure drops across the valve. New materials in globe valve construction also address wear and tear from corrosion and erosion, extending valve life.

High-performance globe valves are now fitting for sectors needing strict control and reliability, like the pharmaceutical and biotech industries. Smart valve technologies are especially useful in industries where precision and data analysis are key.

Securing Effective Flow Management with Globe Valve Insights

Your journey through globe valve components has given you key insights into their design and impact on fluid regulation. From the sturdy body to the precise disc and seat interaction, each part is crucial in meeting the high standards your industry needs. The globe valve’s ability to precisely control conditions makes it a vital tool in industrial applications. As you manage flow in your systems, remember the importance of details.

Reach out to your industrial valve supplier in Russia to learn more about ensuring your valve setup works well and delivers optimal performance and outcomes.