Globe valves are key in fluid systems, offering precise flow control. This article highlights the various globe valve designs, their uses, and the pros and cons. As we delve in, the features and limits of each type will become clear. This knowledge is vital when picking the right valve from your globe valve supplier for your fluid systems.

Understanding Globe Valves

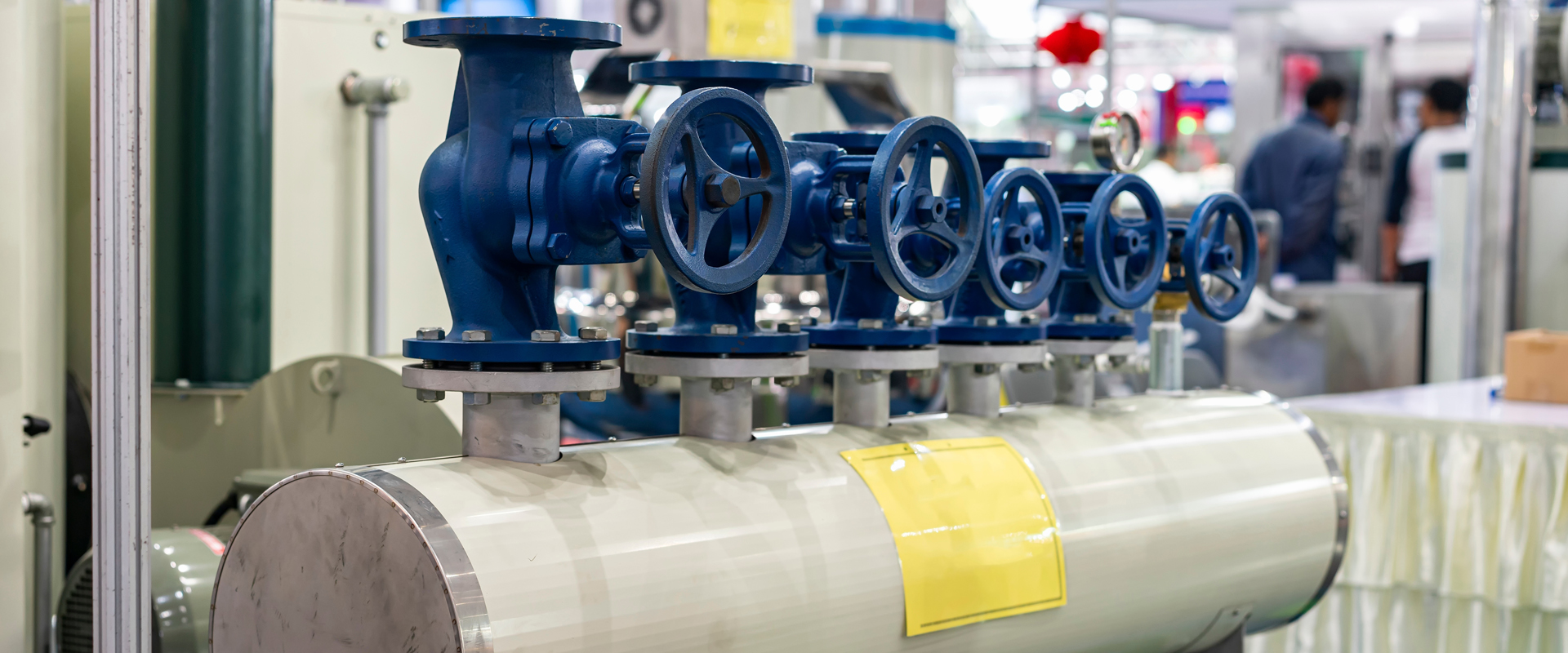

Globe valves are your go-to solution for managing fluid flow. They regulate fluid in systems using linear motion.

A globe valve has a disc that aligns perpendicularly to the seat, allowing precise flow adjustments. The disc moves via a stem, turned by a handwheel or motor. Turning it adjusts the fluid amount passing through the valve. Globe valves have a low leak risk because the disc meets the seat at a right angle, creating a tight seal.

These valves are top-notch for throttling, giving you control over the flow rate. With different designs, you can find one that fits your needs, ensuring effective flow regulation and leak prevention.

Exploring Globe Valve Design Variations and Their Impact

The globe valve's body shape affects flow and pressure. Let us check out how each design impacts these elements.

Z-Body Globe Valve - High Pressure Loss and Applications

The Z-body globe valve, with its Z-shaped partition, causes a high-pressure drop with an L/D coefficient of approximately 340, affecting energy use. It is used where throttling is needed despite the pressure loss.

Y-Body Globe Valve- Reducing Pressure Drop in High-Pressure Services

The Y-body globe valve is great for high-pressure tasks. With a 45-degree angle for the seat and stem, it has a smoother flow, reducing the L/D coefficient to about 55 and lessening pressure loss while allowing good throttling.

Angle Globe Valve- Simplified Flow Path and Fluctuating Conditions

Facing changing flow conditions? The angle globe valve could be your solution. Its 90-degree turn removes the need for an elbow and extra pipe weld, offering a straighter flow route. This design lessens flow disruptions, which is ideal for variable fluid dynamics.

It also has an L/D coefficient of around 150, suitable for changing flow conditions and the slugging effect. This surge in flow can happen in systems with varying flow rates. The angle globe valve's strong design keeps it working smoothly, even under stress.

Materials and Construction of Globe Valves: A Comprehensive Guide

Choosing globe valve materials is critical. They affect the valve's function, lifespan, and fit for certain applications. Globe valves are made from various materials, each with unique benefits.

- Metals, like cast iron, stainless steel, and bronze, are durable and ideal for low and medium pressure, harsh fluids, or marine settings.

- Alloys, such as chrome molybdenum and nickel alloy, withstand extreme temperatures and pressures.

- Plastics are good for low pressure and temperatures. They are light, corrosion-resistant, and cost-effective in industries like pharmaceuticals and food.

AlterValve is a valve supplier that offers a wide range of high-quality industrial valves and parts for various sectors such as power plants, oil and gas, petrochemicals, and more. It sources its products from qualified valve manufacturers and supplies in China, India, and Russia, and ensures that they meet strict quality and safety standards.

Types of Globe Valves Based on Body Bonnet Connection

The connection between the body and bonnet in globe valves matters greatly. Here are the four main types

Bolted Bonnet Globe Valves- Design and Gasket Sealing

Among globe valves, the bolted bonnet type is the most preferred. It uses bolts for a strong connection. A gasket ensures a leak-free seal. Its easy disassembly for maintenance makes it practical. The welded bonnet globe valves offer a different approach with their fixed design.

Welded Bonnet Globe Valves- Lightweight Design for Fixed Systems

Considering globe valves? The welded bonnet type has a light build, perfect for fixed systems. These valves are permanent fixtures welded to the valve body. Their light design is ideal for hard-to-reach or cramped spaces. Welding creates a strong seal, lowering leak risks. While this type is fixed and maintenance-free, other designs, like pressure seal bonnets, work well with changing pressures.

Pressure Seal Bonnet Globe Valves for High Pressure Applications

Choosing valves for high-pressure areas? Pressure seal bonnet globe valves are key. They are designed for tough conditions. As pressure increases, so does the gasket's force, making a better seal. This design ensures strong performance even with pressure changes.

Understanding these valve engineering helps. The gasket reacts to pressure shifts, creating a stronger seal as demands grow. If you need a reliable solution for high-pressure systems, a pressure seal bonnet globe valve is an apt choice since it enables seamless integration. This knowledge can help you make informed decisions while selecting valves for your systems.

Screwed Bonnet Globe Valves- Simplicity for Less Demanding Uses

Screwed bonnet globe valves are simple. They are screwed onto the valve body, ideal for easy conditions and rare use. Their easy assembly and maintenance make them useful for non-complex applications. Knowing when to use this valve type means you can manage fluids well in less critical systems.

Knowing these connections helps pick the right globe valve. Each type has advantages for different situations, so your choice should match your system's needs.

Also Read: Choosing The Right Globe Valve: Selection Tips And Considerations

Operational Pros and Cons of Globe Valves

Understanding the globe valve's operational pros and cons is vital in fluid systems. They are known for excellent shutoff capacity and are great for leak-sensitive systems. They work well for regular use, with a design that lessens the wear on the seat and disc.

However, globe valves have downsides. They can cause high head loss, a big issue for high-pressure lines where shocks might harm internal parts. Large globe valves may require a lot of power and can be noisy.

With these points in mind, you can better judge when to use globe valves. Whether for feed water, chemicals, air, or oil, consider these pros and cons for your system.

Drawing Insights from Globe Valve Applications

Understanding the details about globe valves is vital for anyone dealing with these devices in an industrial setup. While each type has its benefits, remember to consider pressure drops and energy. Use this knowledge to make the most of globe valves in your work. Also, remember to source your valves from trusted valve suppliers and use their guidance for installation, repairs and replacements.