Strainers, those silent workhorses of industrial operations, contribute significantly to your machinery's flawless function. Y-strainers and T-strainers stand out among these. But which one outperforms the other? This comprehensive comparison of Y-strainers vs T-strainers will provide the knowledge you need to make that decision. You are about to understand their design, functionality, and varied applications in detail.

Additionally, you'll learn about their unique advantages and disadvantages. By the end, you will have the necessary information to choose the right strainer for your specific needs. Are you ready to acquire this valuable knowledge? Let's start this enlightening journey.

Understanding Y-strainers and T-strainers

Grasping the details of Y-strainers and T-strainers can revolutionise your industrial operations. This section provides a detailed examination of the design, operation, and uses of these two types of strainers. Armed with this information, you'll be better positioned to make educated choices when deciding between Y-strainers and T-strainers for your particular requirements. Now, let's focus on the specifics of Y-strainers.

What are Y-strainers?

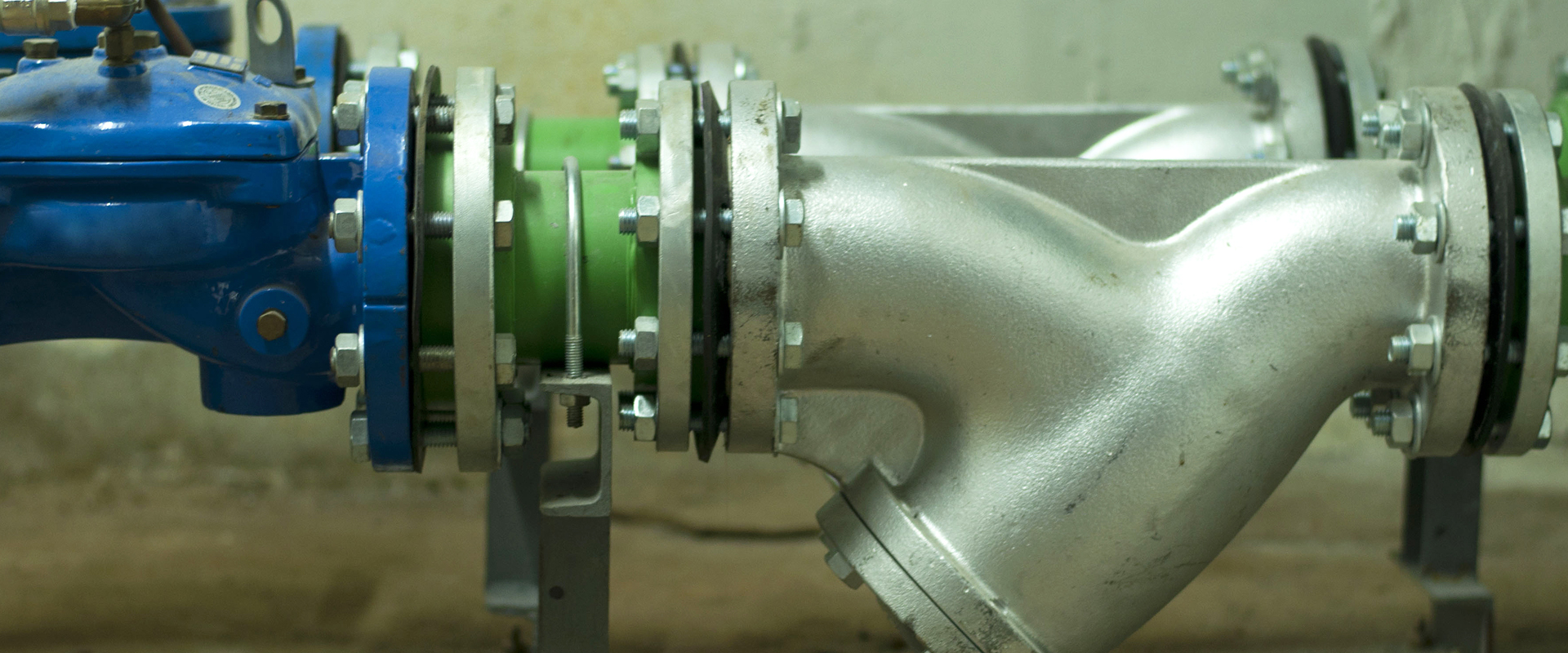

Y-strainers are essential components in pipelines as they prevent contaminants from reaching sensitive equipment. They block unwanted particles and ensure that only clean fluid passes through. This ensures that downstream components operate smoothly. For example, a solenoid valve, which is highly sensitive to dirt, could malfunction if solids disrupt the stream. In such a case, the absence of a Y-strainer could lead to potential damage to the entire system.

In addition to safeguarding solenoid valves, Y-strainers also shield other mechanical equipment such as pumps, turbines, spray nozzles, heat exchangers, condensers, steam traps, and meters. The strainer typically consists of a mesh, perforated metal, or a wedge wire straining element, which filters particulates from steam, gas, or liquid. Y-strainers designed for dirtier applications often come with blow-off valves for easy cleaning.

The efficiency of a Y-strainer primarily depends on the size of the mesh filter. Debris passes through the strainer's openings, measured in microns and mesh size. A micron, a unit that measures tiny particles, and the mesh size, which denotes the number of openings in the mesh per linear inch, typically ranges from a size 3 mesh screen with 6,730 microns to a size 400 mesh screen with 37 microns.

In water handling applications, Y-strainers are often preferred to shield equipment from damage or clogging by unwanted sand, gravel, or other debris.

If you need a Y-strainer, a Y-strainer supplier like AlterValve can assist you in finding a suitable device. Now that we have a clear understanding of Y-strainers, we can proceed to examine T-strainers and compare them.

What are T-strainers?

T-strainers, vital components in many industries, are designed to filter debris and contaminants from liquids and gases. The T-shaped body attaches to the pipeline, enhancing its versatility and user-friendliness.

A T-strainer includes three main parts:

- A T-shaped body

- A removable strainer basket that fits snugly within the body

- A cover that provides easy access to the strainer basket for cleaning or replacement

This design promotes easy pipeline installation and effectively removes debris and contaminants from your liquids and gases. The fluid in your pipeline passes through the strainer, where the basket, made of mesh or another filter material, captures foreign particles. This action protects your downstream equipment, such as pumps and valves, from possible damage.

T-strainers offer several benefits:

- They protect your equipment

- They enhance system efficiency

- They cut down maintenance costs

They come with a quick-opening cover for easy access and are safe even for hazardous processes. The cover can open in a horizontal pipeline without draining the fluid. Their large open area enables media to flow through with minimal restriction, maintaining a low-pressure drop.

T-strainers are prevalent in high-flow applications like water treatment plants, chemical processing facilities, and oil refineries. In essence, T-strainers stand out in versatility and efficiency, making them a preferred choice in various industries. As we move forward, we will compare Y-strainers and T-strainers more closely.

Also read: Exploring the Cost-Effective Role of Y Strainers in Various Industries

Comparing Y-strainers and T-strainers

In the world of strainers, two main types stand out - Y-strainers and T-strainers. Each boasts a unique design and operation method, giving it a distinct identity. As you read through this section, you will understand their specific features and their functionality. This understanding will empower you to make a sound decision when you are choosing between them. Let’s start with the design comparison.

Design Comparison

Have you ever thought about the differences in design between Y-strainers and T-strainers? Understanding their unique design features, installation orientations, and associated costs is essential.

T-strainers have a T-shaped body, a removable strainer basket, and a top access port. These features allow them to collect more particles without blocking, which results in a lower pressure drop. This contrasts with the compact, Y-shaped design of Y-strainers. The mesh in these strainers diverts from the main flow path, preventing the captured particles from blocking the flow. However, they aren't designed to hold large debris and can block quickly, making them better suited for cleaner media and low-pressure applications.

Let's consider installation orientations. T-strainers have some limitations. They can only be installed horizontally with the strainer pointing upwards. In contrast, Y-strainers offer more flexibility. You can install them on either horizontal or vertical piping as long as the filter leg points downwards.

Now, let's discuss costs. Y-strainers are usually more cost-effective due to their cast housing, which is less expensive than T-strainers. Remember, choosing a smaller strainer size before buying can help you save money.

Here are the main differences between Y-strainers and T-strainers:

- T-strainers can collect more particles without becoming blocked, resulting in a lower pressure drop.

- Y-strainers aren't designed to hold a large volume of debris and can block quickly.

- T-strainers can only be installed horizontally with the strainer pointing upwards.

- Y-strainers can be installed on either horizontal or vertical piping.

- Y-strainers are typically more affordable due to their cast housing.

Operational Comparison

The operational mechanics of Y-strainers and T-strainers show significant differences, especially in their maintenance requirements and suitability for different applications.

T-strainers, ideal for heavy-duty applications, can handle a large amount of debris without clogging. This feature makes them perfect for applications involving fluids filled with a lot of debris. Furthermore, the maintenance of T-strainers is simple. Their design includes a quick-opening cover for easy access, and if you install them in a horizontal pipeline, you can open the cover safely without having to drain the fluid. On the other hand, Y-strainers work better with cleaner media and low-pressure applications. Even though they might not hold as much debris, they are easier to install and maintain. However, keep in mind that their design might make them clog quickly if the fluid has a lot of debris.

So, the question is, Y-strainers or T-strainers: which is better? The answer depends on your specific needs. You need to take into account the type of fluid, the amount of debris in it, and the acceptable pressure drop. Both Y-strainers and T-strainers offer unique operational benefits. However, the choice between the two largely depends on the specifics of your application. As we further explore each strainer type's unique advantages and disadvantages, it will become clearer which one best suits your requirements.

Pros and Cons of Y-strainers and T-strainers

In your journey to understand Y-strainers and T-strainers, you'll examine the pros and cons of each. This examination will give you a balanced understanding of their performance and possible limitations. This understanding will guide you in making an informed choice between Y-strainers and T-strainers. So, let's begin this informative journey.

Pros and Cons of Y-strainers

Y-strainers serve a vital protective function. They shield various mechanical equipment, such as solenoid valves, pumps, and turbines, from potential harm caused by debris in the fluid. Furthermore, Y-strainers offer a cost-effective solution.

Despite these benefits, Y-strainers carry certain limitations:

- They can only hold a limited amount of debris, which could result in quicker clogging than is ideal.

- They work better with cleaner media and applications that operate under less pressure.

- They demand regular and detailed cleaning, with some models even requiring a complete scrubbing of their metal mesh strainers.

- There's a chance of experiencing a higher pressure drop, especially if the fluid transports a large quantity of debris.

In conclusion, while Y-strainers offer protection and cost benefits, their appropriateness largely hinges on the media's cleanliness and the application's pressure.

Now that we have considered the pros and cons of Y-strainers let's shift our focus to T-strainers and evaluate how they measure up.

AlterValve is a valve supplier that offers a wide range of high-quality industrial valves and parts for various sectors such as power plants, oil and gas, petrochemicals, and more. It sources its products from qualified valve manufacturers and supplies in China, India, and Russia, and ensures that they meet strict quality and safety standards.

Pros and Cons of T-strainers

We'll start by looking at the benefits of T-strainers. Perfectly suited for heavy-duty tasks, T-strainers perform well when managing fluids that contain a lot of debris. The ease of maintenance for these strainers comes from their quick-opening cover. This cover makes access simple and ensures safety in dangerous processes.

Despite their advantages, the design of T-strainers does have some drawbacks. You can only install them horizontally with the orientation facing upwards. This could potentially limit your system's design possibilities. Furthermore, T-strainers often cost more than Y-strainers because of their intricate design and manufacturing process.

After considering the advantages and disadvantages of T-strainers, we can now examine how to choose wisely between Y-strainers and T-strainers.

Choosing Between Y-strainers and T-strainers

When selecting a filter, either a Y-strainer or a T-strainer, you must consider various factors carefully. Both strainers find use in inline settings with horizontal flow directions. A Y-strainer has an inlet and outlet in opposite directions, while the T-strainer's outlet stands at a right angle to the inlet.

The type of particle you aim to filter is a crucial factor. Are you filtering water that contains inorganic materials like sand? Or are you dealing with a pond filled with organic matter such as leaves and algae? The nature and size of the particle will help you decide the suitable micron/mesh size for your filter.

The size and nature of the connection also significantly influence the choice of a strainer. Ensuring the strainer's material agrees with the fluid being filtered is crucial. Here are some crucial considerations when choosing a strainer:

- The strainer should accommodate the system's maximum flow rate.

- The strainer needs to endure the system's operating pressure.

- The pressure difference across the strainer should stay within acceptable limits.

- Think about the cost of operating the strainer, which includes maintenance and replacement expenses.

- Safety is of utmost importance. The strainer should not present any risk to the operator or the environment.

In conclusion, the decision to choose a Y-strainer or a T-strainer depends on your specific application requirements. These might encompass the type of fluid, the amount of debris in the fluid, and the acceptable pressure difference.

Choosing Wisely: Y-strainers vs T-strainers

In the industrial world, the importance of understanding the details of Y-strainers and T-strainers cannot be overstressed. Both come with unique designs, operations, and applications, each crafted to cater to specific needs. At times, Y-strainers might outshine in certain situations, while T-strainers could turn out to be an ideal fit in others. It's crucial to grasp their strong points and weak points to make an informed decision. Keep in mind, that the selection of the right strainer can significantly enhance your system's efficiency. For further assistance in selecting the ideal strainer for your operations, our team of AlterValve experts, a trusted valve supplier, is ready to provide guidance and support. As an industry veteran wisely said, "Choosing the right tool is the stepping stone to operational efficiency."