Have you ever tried to picture an industry without valves? It's challenging, isn't it? These fundamental components are omnipresent, ensuring that our industries function smoothly and efficiently. As a significant part of your role, you comprehend the importance of picking the suitable valve, but it often poses a challenge. This article aims to ease your decision-making process. It will introduce you to various industrial valves and ultimately lead you to make an informed decision. So, take a breather, and let's start exploring the fascinating world of industrial valves.

Understanding Different Types of Industrial Valves

Each type, whether gate valves, globe valves, ball valves, butterfly valves, or check valves, possesses a unique design and finds its specific use in the industry. Let's examine these types individually.

Gate Valves

Gate valves, also known as sluice valves, are versatile and efficient, making them a vital element in numerous industrial applications. They are significant in oil and gas production, water treatment, power generation, chemical processing, wastewater management, and residential plumbing systems. For example, in the oil and gas industry, gate valves regulate the flow of hydrocarbons. Water treatment plants employ them for fluid diversion and treatment processes. Given their wide-ranging applications, understanding their operation and features is essential.

As a multi-turn valve, gate valves perform best when fully opened or fully closed. They act as isolating valves in piping systems. Understanding their function requires knowledge of their operation. They also contribute significantly to maintenance, repair works, and new installations. They isolate specific sections of the supply network and redirect fluid flow throughout the pipeline.

Here are some key features of gate valves:

- Operation: Gate valves function by lifting a circular or rectangular gate out of the fluid path.

- Types: Parallel and wedge-shaped are the two main types of gate valves.

- Design: Gate valves come with rising stems or non-rising stems, solid wedges, flexible wedges, or split wedges.

- Unique Feature: Gate valves have a unique feature of linear disc movement. The disc, either gate or wedge-shaped, provides an effective shut-off and on mechanism.

These valves are perfect for isolation, handling wastewater applications, and neutral liquids. They can regulate gases between -200C and 700C under a maximum pressure of 16 bar. For slurries and powder media, knife gate valves are often the choice.

With a solid understanding of gate valves, we can now explore other types of industrial valves.

Globe Valves

Moving on from gate valves, we focus on another key valve type - the Globe Valve. As a member of the linear motion valve family, the design of globe valves allows them to regulate, stop, and start fluid flow. This is achieved through a disk mechanism that can either open or close the pathway of the flow, making them adaptable for both manual and automatic operations in plant piping.

When designing globe valves, it's essential to pay close attention to factors such as flow control range, duty, and pressure drop. Meeting these factors is crucial to prevent premature failure and ensure reliable service. Given their exposure to higher differential pressure, globe valves demand a specially designed valve trim.

Globe valves are used in a variety of applications, which include:

- Fuel oil systems

- Cooling water systems

- High point vents and low point drains

- Feedwater

- Boiler vents and drains

- Turbine seals and drains

- Turbine lube oil systems

They offer several benefits, such as:

- Effective flow regulation

- Moderate throttling capacities

- Ability to function as a stop check valve even without the disk

- Easily machinable or resurface-able seats

However, they do have a few drawbacks:

- High-pressure differentials or drops

- Need for a stronger force or an actuator to seat the valve

Given their wide range of applications and the balance between their advantages and disadvantages, globe valves play an essential role in industrial and construction projects. In the following section, we will further our discussion on industrial valves, focusing on another key type and its significance in various industries.

Also read: Preventing Valve Leakages: Innovative Solutions for Common Valve Repairs

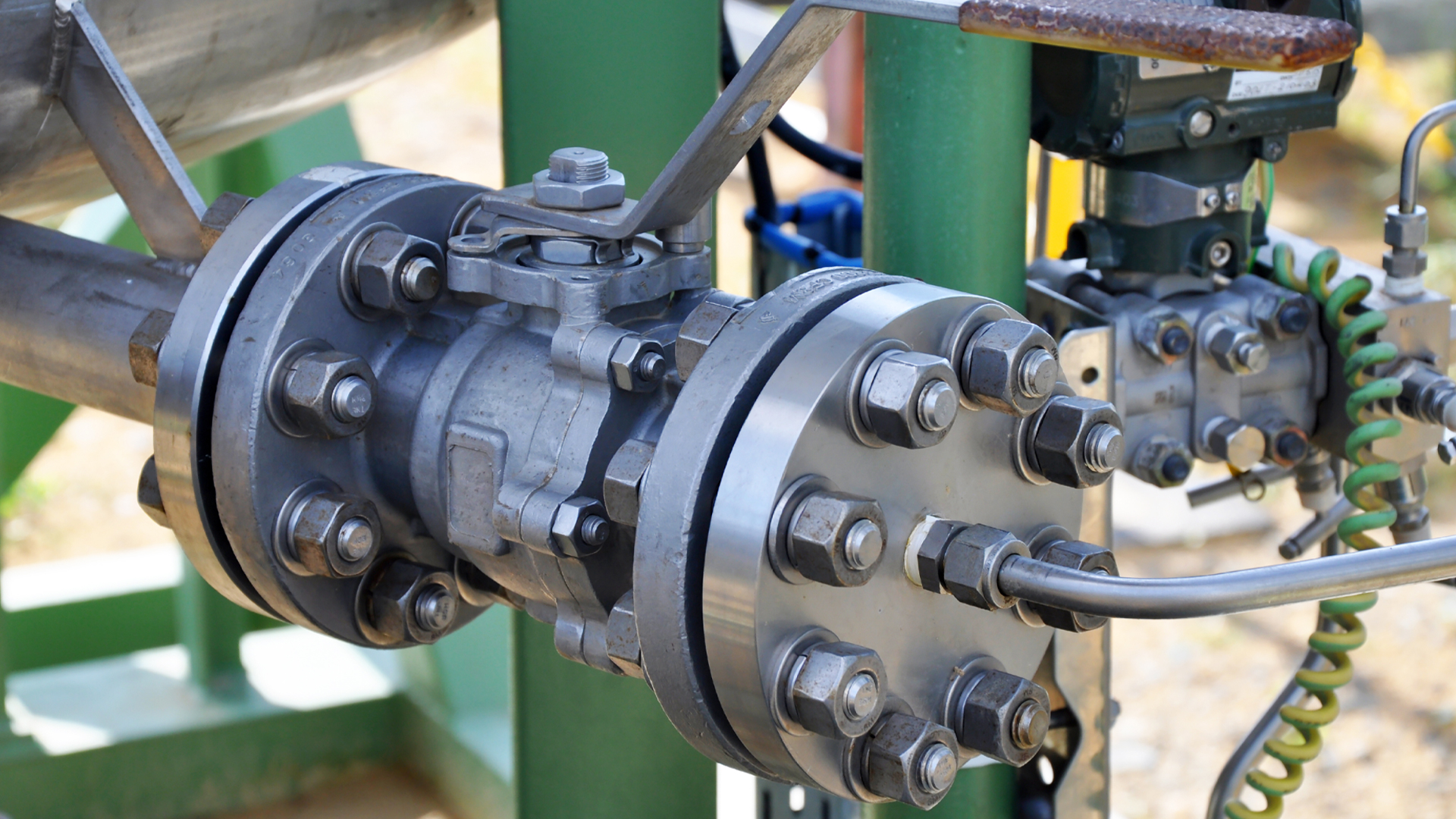

Ball Valves

Ball valves regulate flow rates in gas pipelines and chemical processes, and they manage temperature or pressure in tanks or vessels that hold hazardous materials. Their strong shutoff, high flow, and fast operation make them perfect for transporting natural gas, crude oil, and other refined products.

In onshore and offshore oil and gas production facilities, ball valves function as fluid shutoff valves. They also find use in fuel gas systems that supply furnaces.

To comprehend the increasing demand for ball valves, we must examine their technical aspects. Ball valves, a part of the quarter-turn valve family, use a hollow, ball-shaped disc to control media flow. Here are some key features and applications:

- Applicable for various uses: They are fit for applications that need bubble-tight shutdown, including fluid, gaseous, and vapour.

- Favoured choice: Ball valves are a favoured choice in many industries.

Butterfly Valves

Our discussion on industrial valves now focuses on a critical type - the butterfly valve. This valve, with its disc-shaped design similar to a butterfly's wings, is a preferred option for managing fluid flow.

These valves find use in a range of sectors. Oil and gas, water treatment, chemical processing, and HVAC systems are just a few. Car manufacturing also employs these valves.

The pharmaceutical industry deserves a special mention, where butterfly valves hold a significant role. They manage fluid flow in pipelines and hold an essential place in drug manufacturing, sterile processes, and cleanrooms. In this sector, you can opt for a range of butterfly valves, such as:

- Concentric

- Double-offset

- Triple-offset

What makes butterfly valves stand out? Here are some of their unique features and benefits:

- Their compact design enables easy fitting into tight spaces.

- They come with fewer components, making them cost-effective compared to other valve types.

- Their design supports quick disassembly and reassembly, simplifying maintenance.

- They are quick-acting and adjustable, enhancing efficiency and precision in flow control.

- Their streamlined design leads to a lower pressure drop across the valve, fostering energy efficiency in flow control systems.

Butterfly valves manage and regulate flow. The valve's obturator turns at right angles to the flow direction, allowing flow to surpass it when open. The unique flat-to-concave disc that attaches to the valve stem distinguishes butterfly valves from other types of industrial valves. They find common use in water and gas applications where there's a need to isolate or interrupt media flow. They also suit industries using large-diameter pipes and work well with slurries, cryogenics, and vacuum services.

Check Valves

Check valves, one-way or non-return valves, are crucial in piping systems. They stop backflow and ensure that fluid only flows in one direction. Their main job is to stop the process flow from reversing, as this could potentially damage equipment or interrupt the process. You will usually find these valves protecting pumps in liquid applications or compressors in gas systems, where backflow could cause the pump or compressor to shut down.

Here are some key points about check valves:

- They are often used in feed pumps in steam boilers and various processes in chemical and power plants.

- They are even used when a mixture of gases is being transported in a single pipeline.

Moving on to the market scenario, check valves, being a type of industrial valve, are used in industries that contribute significantly to India's GDP. This hints at a high future demand for these valves in India.

AlterValve secures premium industrial valves and parts from leading global manufacturers, tailored to meet the needs of diverse sectors such as power plants, oil and gas, petrochemicals in China, India, and Russia. Our commitment to quality and safety ensures that our products meet the highest standards, guaranteeing reliable performance across all industries.

Wrapping It Up

Understanding the unique benefits and drawbacks each type of industrial valve provides, the next step involves selecting the appropriate one for your requirements. This choice should consider the type of fluid you'll manage, the pressure and temperature conditions, and the necessary level of flow control.

Here is a detailed look at each type:

- Gate valves: These valves are popular for managing thick liquids and are cost-effective. Numerous industries use them, but their design makes them unsuitable for throttling.

- Globe valves: These are excellent for throttling applications. They offer precise flow control, making them the preferred choice when exact fluid flow regulation is necessary. However, their higher cost may be a concern for some businesses.

- Ball valves: These valves are popular for their durability and longevity. They're simple to operate but may not be the best choice for managing viscous fluids or when precise flow control is essential.

- Butterfly valves: These are lightweight, compact, and cost-effective, making them a favourite in many sectors. However, they may not perform well in high-pressure situations.

With this knowledge at your disposal, you can evaluate the pros and cons, consider your specific application requirements, and make a knowledgeable decision. When you're prepared to buy connect with AlterValve, your trusted industry valve supplier, to find the perfect industrial valves for your specific application.