Ever wonder what goes into making a valve body? It is one of the vital valve parts that plays a key role in how well it functions. From sturdy carbon steel to adaptable stainless steel and the latest special alloys, your material choice shapes your valve’s performance. Let us dive into how these valve parts selection affects your valve's success in tough spots.

Overview of Valve Body Materials

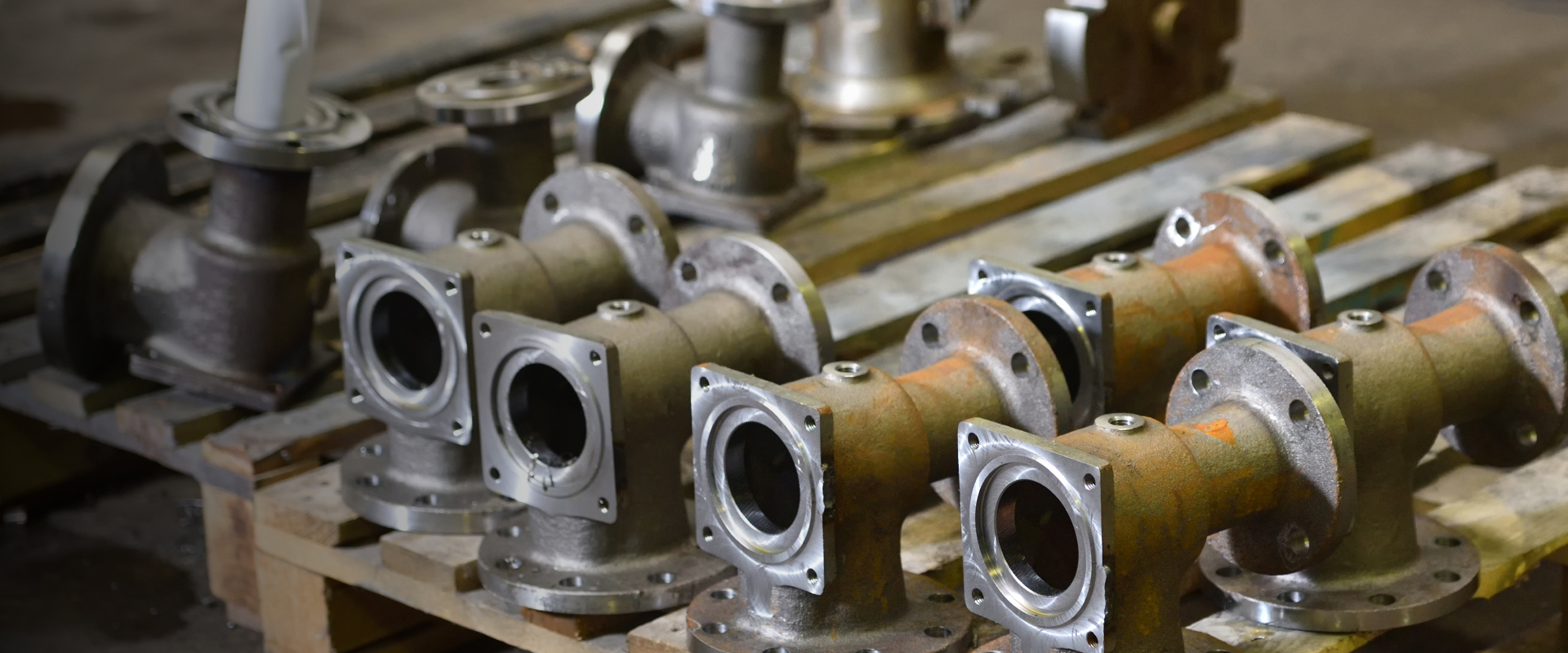

Valve bodies are the core of flow control in your pipelines. They house parts like stems, seats, and discs to manage flow, pressure, and temperature.

Various materials are used, each chosen for suitability to meet specific requirements. From cast iron and stainless steel to plastics and alloys, the material sways the valve's role and the fluid it deals with.

As you weigh your options, consider how well the material gels with the fluid, its lasting power, and its fight against rust. The right pick means your valve works smoothly, keeping fluid flow in check.

Our blog breaks down the intricate details associated with valve materials to help you make a well-informed decision when investing in industrial valves. Let us read on.

Criteria for Selecting Valve Body Materials

In the valve-making game, knowing what materials to pick is key. You want your valves to stand up to what they will face.

Here are three criteria to consider when picking your materials:

With these in mind, finding the right balance between what you need and what you can spend is vital. This sets the stage for a valve that can take on tough conditions with ease.

1. Impact of Temperature

Most industrial environments deal with temperature extremes. Hence, this criterion matters a lot. Temperature modifies how well materials work, so pick ones that can handle your operational heat or cold specifications. Carbon, steel and stainless steel are often the top picks for high heat. If the application requires extremely low temperatures, using materials such as bronze would be more suitable.

Ensuring the material can handle the system's pressure extremities is key to preventing leaks and other major issues.

2. Influence of Pressure

Picking appropriate materials for valve bodies is crucial, as they need to be strong enough to withstand the highest pressure during the operation. High-pressure applications require super strong and durable materials to ensure optimum performance and safety.

3. Media Compatibility and Corrosion Resistance

Media compatibility and corrosion resistance are high-priority criteria. The valve material must withstand the specific media it controls without deteriorating under corrosion, even if it works in extremely harsh conditions. Here are some options to consider:

- The best rust-proof material for valves is stainless steel, which can withstand any rust-prone environment.

- The next top pick for rust fight is Monel, a nickel superalloy that is great in seawater and salt spots. It also supports some chemicals, making it ideal in super rust-prone spots.

- Alloy C 276 is the best choice for chemical plants. This nickel molybdenum chromium alloy with a bit of tungsten is highly effective at fighting rust and also aligns with harsh media.

- PVC and PP are preferred for spots where non-metal options are better for their rust resistance and lightweight. For instance, PVC valves work effectively in applications using chloride solutions and seawater. PP valves can withstand corrosion from water solutions, acids, and bases.

Using this information, you can make informed decisions regarding the materials that will help your valves perform well in various industrial settings.

Also Read: Key Considerations for Selecting the Optimal Valve Body Material

Most Common Materials Used for Valve Bodies

In the valve-making world, especially in chemical, water treatment, and oil and gas, knowing your materials is a must. These picks are not random. They are chosen for how well they fit with specific needs.

Some materials are often picked for their special traits and fit for different valve-making uses. Here are the top five materials used for valve bodies.

Knowing these materials' general traits and uses is key to making smart picks that match your industry's specific needs, ensuring your valve bodies do well and last long.

1. Cast Iron Variants in Valve Body Manufacturing

Cast iron types like grey cast iron and ductile cast iron are big names in the field. Grey cast iron is often used in water, steam, oil, and gas applications and is right for low-pressure valves.

Ductile cast iron, with its nodular graphite build, has better mechanical traits, making it a strong pick for some applications with higher pressures.

Carbon and Alloy Steels for Valve Bodies

Carbon and alloy steels are ideal for applications where iron and bronze valves are insufficient. Carbon steel, for one, has become big because of its efficacy and tolerance against stress from heat growth, impact loads, and pipeline shape changes. These materials are also good for medium and high-pressure valves, often used in steam, hot and cold oil, liquid gas, compressed air, water, and natural gas applications.

Alloys are steels with added elements to improve strength, wear, and corrosion resistance. These additions can significantly enhance the material's performance in specific applications. For example, adding chromium and nickel to stainless steel provides excellent rust resistance and strength, making it ideal for high-pressure systems and areas prone to rust.

When considering carbon or alloys, It is key to consider their fight against heat stress and how well they fit with the media they operate with.

3. Stainless Steel and Special Alloys for Valve Bodies

Stainless steel combined with iron, chromium, and nickel is perfect for use in water treatment, steam work, and chloride full spots, as well as in the food and drink field because it fights rust and oxidation.

Special alloys, like molybdenum, are must-haves in the chemical field for dealing with different acids and industrial chemicals. Their ability to fight rust makes them a top pick for valves in tough spots. The toughness of superalloys like Inconel and Monel are highly preferred in industries where durability and corrosion resistance are key.

Plastics and Elastomers: Non-Metallic Valve Body Options

While searching for the best valve bodybuilding materials, you may have considered metals due to their strength and lasting power. But there is a growing move to use non-metal options, like plastics and elastomers, in certain cases. These materials have unique advantages, especially if you want corrosion-resistant and lightweight materials.

Valves made of plastic have become popular due to their superior rust resistance. Unlike metals, plastics can withstand exposure to a wide range of chemicals that normally cause rust in metals. This makes them perfect for chemical industries dealing with corrosive media. Moreover, plastics are naturally light, which can be an advantage for installation and maintenance.

At the same time, It is key to know that while plastics and elastomers have many benefits, they are not ideal for all conditions. With smart design and material selection, the limitations of plastics and elastomers can be overcome to maximise their benefits.

AlterValve secures high-quality industrial valves and parts from leading manufacturers worldwide, designed to meet the requirements of various sectors such as power plants, oil and gas, and petrochemicals in China, India, and Russia. Our steadfast commitment to quality and safety guarantees that our products adhere to the highest standards, delivering reliable performance across industries.

Valve Body Material Compatibility in Industry Applications

Your valve material must meet specific industrial and application requirements. Here is a compilation of the various industries and their valve compatibility

Oil and Gas Industry

Valve body materials used in the oil and gas field include carbon steel, stainless steel, and ductile cast iron. Carbon steel is known for its ability to withstand heat stress, while stainless steel offers top rust resistance, and ductile cast iron balances strength and stretchiness.

Chemical Processing Industry

In chemical industries, picking valve body materials that can handle a lot of tough chemicals is key. These materials must handle acids, alkalis, solvents, and other rust-prone stuff, ensuring your whole process is safe and whole. The top material choices for this industry are:

- Stainless steel

- Hastelloy

- Iconel

- Monel

The chemical industry does not forgive shortcuts or quality compromises. So, pick smart, and make sure your valves can take on the challenge.

Standards and Specifications for Valve Body Materials

In valve manufacturing, adhering to specific standards and details is not just about compliance but rather ensuring quality and safety. Standards are key in the valve-making process. They are a mark of quality, ensuring every valve body can handle the set pressures and temperatures. This is key to preventing failures that could lead to leaks, spills, or big accidents.

This adherence to rules ensures end users' safety and upholds your reputation as a manufacturer who values safety and reliability.

While standards are key, they are just one part of the material choice puzzle. You should also consider:

- The valve size

- Type of connection

- Operational requirements

- Wear and tear

- Maintenance essentials

- Ease of availability for replacements

By thinking carefully about these extra factors, you can ensure your valve not only fits smoothly into your system but also lasts through time.

The Material Influence on Valve Longevity

Choosing the right valve material determines the success or failure of your industrial operations. There are no hard and fast rules to arrive at a choice. It requires a thorough analysis of your industrial requirements and knowledge of the materials and their attributes.

Do reach out to AlterValve, the reputed valve suppliers to help you with this process. Their expertise and experience will be handy in helping you find the right valve that lasts for years.