Every valve choice affects how well your fluid systems work, impacting their safety and how well they perform. When working with different media like gas, water, or other substances, It is crucial to consider the interplay of valve type, its compatibility with the material, and the setting it will be used in.

This complex process leans on your systems engineering knowledge to ensure your operation runs smoothly and upkeep is hassle-free. Realising the weight of this task sets you up for a strong and effective system. Discover how your skills can guide you to make smart choices when picking valves.

Understanding Valve Functionality and System Design Impact

Your mission in selecting valves is to grasp their role in the systems blueprint. Valves are the traffic cops of flow within pipes, managing the movement of diverse materials. Their impact is broad, touching on the system’s performance, dependability, and effectiveness. A well-picked control valve will keep the desired flow and pressure, enhancing the system's peak performance.

Yet, the wrong valve can have dire effects. Imagine the increased downtime for fixes or full-on system failures. The risk to safety climbs if the valve can't meet the system's operational needs. Poor choices can lead to subpar system function and avoidable safety issues.

With these risks in mind, it is evident that pinpointing the exact needs of the fluid you are dealing with is vital in picking valves. Each fluid demands a valve that is made of the right stuff and shaped to fit, keeping issues like rust or wear at bay. Knowing the fluid type makes you consider which valves will play nicely with it.

Selecting Valves Based on Fluid Type and Compatibility

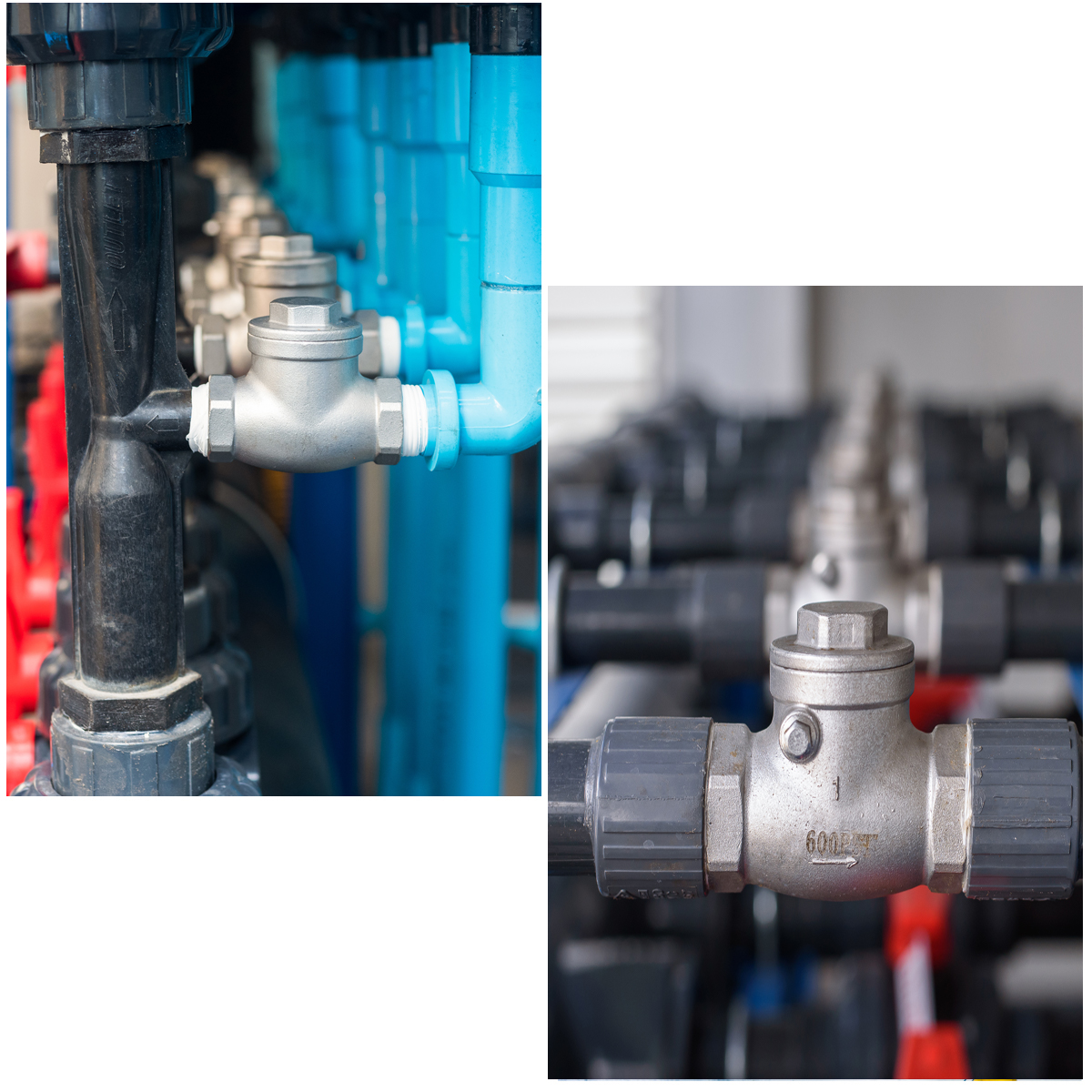

Whether it is water, gas, oil, or harsh chemicals, your media guides your valve choice. Each fluid type calls for a certain valve and material for best results. Here is what you need to know:

- Ball valves are top-notch for water and gas, thanks to their tight seal.

- Diaphragm valves are the go-to for corrosive substances, ensuring a tight shutoff in clean applications.

The material making up the valve must stand up to the fluids' traits, with options like stainless steel and brass offering resilience in some cases and plastic valves excelling in fighting off chemical wear.

Pressure and Temperature Considerations in Valve Selection

Valves are made to handle set pressure and temperature limits, and ignoring these can cause valve failure, putting your system at risk. It is key to picking a valve to manage the media's heat and environmental conditions. High heat can make sealing materials change shape, which might lead to leaks or valve failure if not considered when choosing.

Ensuring valves are tested for extreme heat and pressure is a must to ensure they will work well under tough conditions. As you weigh how a valve will fare in its future setting, remember your system's resilience relies on these important details.

Determining the Correct Valve Size and Flow Rate for Your System

The right valve size and knowing the flow rate are crucial for your fluid system work and dependability. The flow coefficient, or Cv, is vital in valve sizing. It shows how much water can move through a valve with a one psi drop in pressure. This helps match the valve size to the needed flow rate, keeping your system running smoothly.

To get the valve size and pipeline size to match up, consider the Cv in light of your pipe size and the amount of fluid you need to control. Sizing it wrong can lessen system work and even cause an early system failure.

Talking to valve makers for exact Cv numbers and sizing advice is a key step. As you mull over these points, also think about the materials of the valves, as they greatly affect how long they last and how well they work.

Material Selection for Valve Durability and Performance

The right material helps the valve resist rust, erosion, and wear. all vital for its life span and trustworthiness. Here are some common materials and their uses:

- Stainless steel is great at fighting off rust, making it a fit for many settings, including those with corrosive fluids.

- Carbon steel is strong but can rust, so it might not be best for systems with corrosive elements.

- Brass offers decent rust resistance and sturdiness and is often used in water systems.

- Plastic valves are a rust-proof choice for dealing with harsh chemicals that could damage metal valves.

While picking the right material is basic, it is also key to consider upkeep and fixes to keep your system working well.

Also Read: Charting the Course for Triumph in Russian Industrial Valve Manufacturing

Maintenance, Repair, and Operational Efficiency

In choosing valves, ponder their upkeep and repair needs. Valves that need lots of maintenance can cause more system downtime, while those made for longer runs without upkeep can boost work and cut costs over time.

It is vital that valves are easy to get to for fixes, saving time and money. Having spare parts on hand is also key, as it can stop long waits when repairs are needed.

Work efficiency is tied to how well a valve can do its job with little fuss. By picking the right valve, you can cut downtime and keep a trusty system. As you weigh these points, balance the initial costs against long-term savings for your project's success.

Cost Effectiveness and Value in Valve Selection

In evaluating valves weigh their price against their sturdiness, trustworthiness, and upkeep needs. A valve that gives you the most bang for your buck should fit your project specs and add to system work and life span.

Think about long-term costs, such as the money saved from less maintenance and better system work. Choosing valves that can take what your system dishes out can stop costly downtime and make your system last longer, helping the environment by cutting waste and the need for frequent replacements.

Optimising Your System Through Strategic Valve Choice

Taking the right steps in valve choice is key for an effective, safe, and reliable system. It needs a strategy that looks at technical specs and how tough the material is, ensuring it is right for the pressures, heat, and flow in your system.

Make smart choices with the help of your industrial valve supplier in Russia. By choosing valves that follow these rules, your expertise makes your project a win and keeps it going strong.