In the intricate realm of industrial filtration, you are often tasked with choosing the best strainer for your system's protection and efficiency. Delving into basket strainers versus Y strainers, we uncover their unique strengths. These devices are pivotal in keeping your machinery free from harmful particulates.

As we explore the specifics, insights emerge to guide your informed decision-making. Let us dive into the details and discover which strainer might claim victory in your situation.

Understanding Strainers in Industrial Applications

Y-strainer suppliers say that these devices are the unsung protectors in the industrial world. They capture larger objects like dust and sediment and guard crucial parts such as valves, steam traps, and pumps. Strainers' main role is to shield equipment, promoting seamless and uninterrupted system function.

Strainers protect against costly downtime. When a system halts, financial losses can skyrocket. By keeping debris away from machinery, strainers are fundamental to constant operation, especially in sectors where time equals money.

Strainers have vast environmental and operational perks, from oil to water treatment and chemical production. They play a protective role in pipelines, minimising the ecological footprint. Their design and purpose are fundamental to maintaining the integrity and productivity of industrial setups.

Strainer vs. Filter Key Differences Explained

Navigating industrial systems often leads to confusion between strainers and filters. Here is a brief breakdown of their differences:

- Filters catch tiny impurities, invisible to the eye, targeting specific micron sizes.

- Filters usually have a one-time use medium and are not for repeated use.

- Once full, they must be swapped out, affecting operational costs and upkeep.

Understanding these distinctions aids in picking the right equipment for your industrial needs. Y- type strainers, for instance, meet specific requirements with their design and functionality.

Y-type Strainer Design, Applications, and Advantages

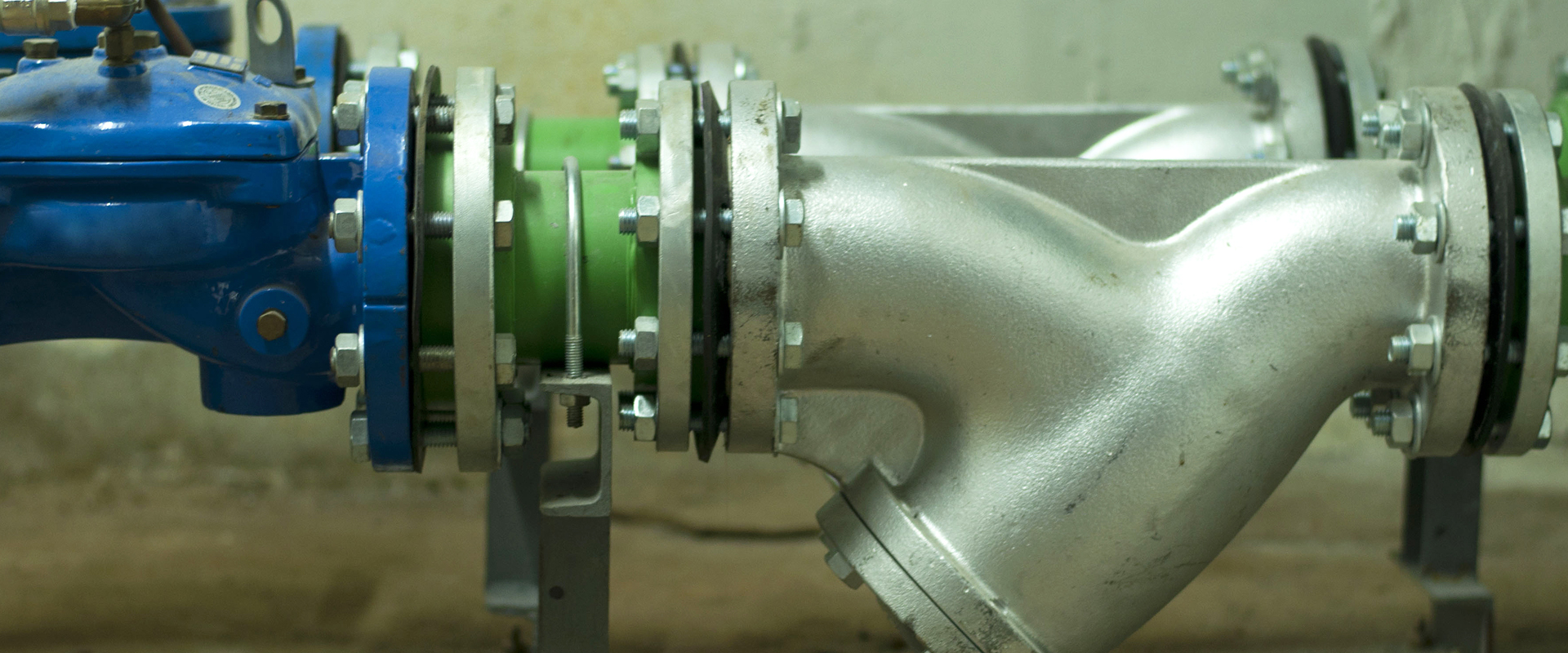

Shaped like the letter Y, these strainers are ideal for coarse filtration, removing big particles from the flow. They enhance clearance in the medium, extending the life of pumps and meters.

Y-type strainers excel in steam and gas applications because they can handle high pressures. They also defend against common liquid system threats like gravel and sand. Plus, they can be set up either vertically or horizontally, giving you installation flexibility.

They come in various materials, like carbon, stainless steel, or cast iron, to fit different industrial needs. They are a strong choice for many sectors, balancing effective filtration, installation ease, and cost savings. Their shape is also perfect for petroleum and other fluid uses, especially where high flow is needed.

Y strainer’s Suitability for Various Media

Y strainers perform well across different media. They are stellar in steam and gas scenarios, where high-pressure handling is critical. They are also great at managing liquid applications and catching debris such as gravel and sand.

Basket type Strainer- Design, Applications, and Advantages

Basket-type strainers stand out due to their horizontal installation preference. This setup relates to the position of the basket seals and the drain ports. They are the top pick for high-flow needs, with simple servicing via cover removal for basket access.

Basket strainers are vital in liquid service uses. They are often linked to pump suction, filtering out solids bigger than the mesh, and shielding the system's inner parts from harm. The design allows for easy upkeep, aligning with industrial system maintenance demands.

Duplex styles in basket strainers provide uninterrupted flow benefits. They have two baskets and valves, so one can be cleaned while the other works.

Selecting between strainers is not just a preference. It is about application fit. Duplex designs show the inventive solutions, keeping processes efficient and ongoing.

Basket Strainers Role in High-Flow Capacity Systems

Basket strainers are notably efficient in high-demand systems. Duplex strainers, especially, are precious for maintaining operation. They let you clean one basket while the other keeps going, avoiding downtime and upholding process integrity.

Basket Strainer vs Y Strainer Comparative Analysis

Basket strainers and Y strainers each have their own designs, installation needs, and upkeep considerations. Basket strainers prefer horizontal setups, while Y strainers can go both ways, offering versatility.

Basket strainers are limited to horizontal positions, but Y strainers can fit into various spaces. Maintenance-wise, basket strainers need the cover removed to clean the basket. Y strainers handle high pressures well and are budget-friendly, but they might need system pauses for cleaning, a vital point for continuous operations.

Basket strainers are perfect for high-flow liquid uses and allow servicing without stopping the flow. They are also better for easily contaminated media, holding more dirt between cleans.

Y strainers are compact and withstand higher pressures, fitting steam and gas uses where space is tight. However, due to lower open area ratios, they might not be best for heavy particle loads.

Applications like liquid services tied to pump suction need basket strainers for protection. Y strainers, handling high pressures, are more apt for steam and gas uses with gravel and sand.

Also Read: How the Y-strainer Works- Essential Insights for Industrial Piping Systems

Installation Flexibility and Orientation for Strainers

The installation adaptability of a strainer is key in industrial applications. Y strainers are adaptable, fitting into horizontal and vertical spaces. Although efficient in liquid filtration, basket strainers are mostly for horizontal setups. When picking a strainer, consider the operational pressure and contamination levels central to strainer performance.

Pressure and Contamination Considerations in Strainer Selection

Picking the suitable strainer requires considering pressure capacity and contamination. Y strainers can handle more pressure, suiting certain uses. Basket strainers excel in environments prone to contamination, effectively trapping debris. Both pressure and contamination are vital in finding the most fitting strainer type.

Strainers Simplified- Making the Right Choice for Your System

After assessing basket and Y strainers, the significance of the correct choice for your industrial needs is clear. Whether maximising flow in liquid uses or managing high-pressure settings, your decision affects your system's reliability and lifespan. Think about each strainer's installation ease and operational perks.

To simplify your decision, get expert advice from your industrial valve supplier in Russia. Always rely on expert guidance when investing in valves and y-strainers.