Imagine you are at a junction with numerous paths, each leading to a different ball valve choice. Your role in engineering, upkeep, or buying has brought you to this point, where size, build, function, and approval marks come together for your fluid control system's smooth operation.

Ball valve suppliers say it is vital to understand these elements to make a smart choice that satisfies your work settings and detailed needs. With a clear, step-by-step method, the art of choosing a ball valve becomes transparent, allowing you to make a lasting decision.

Understanding Ball Valve- Basics and Types

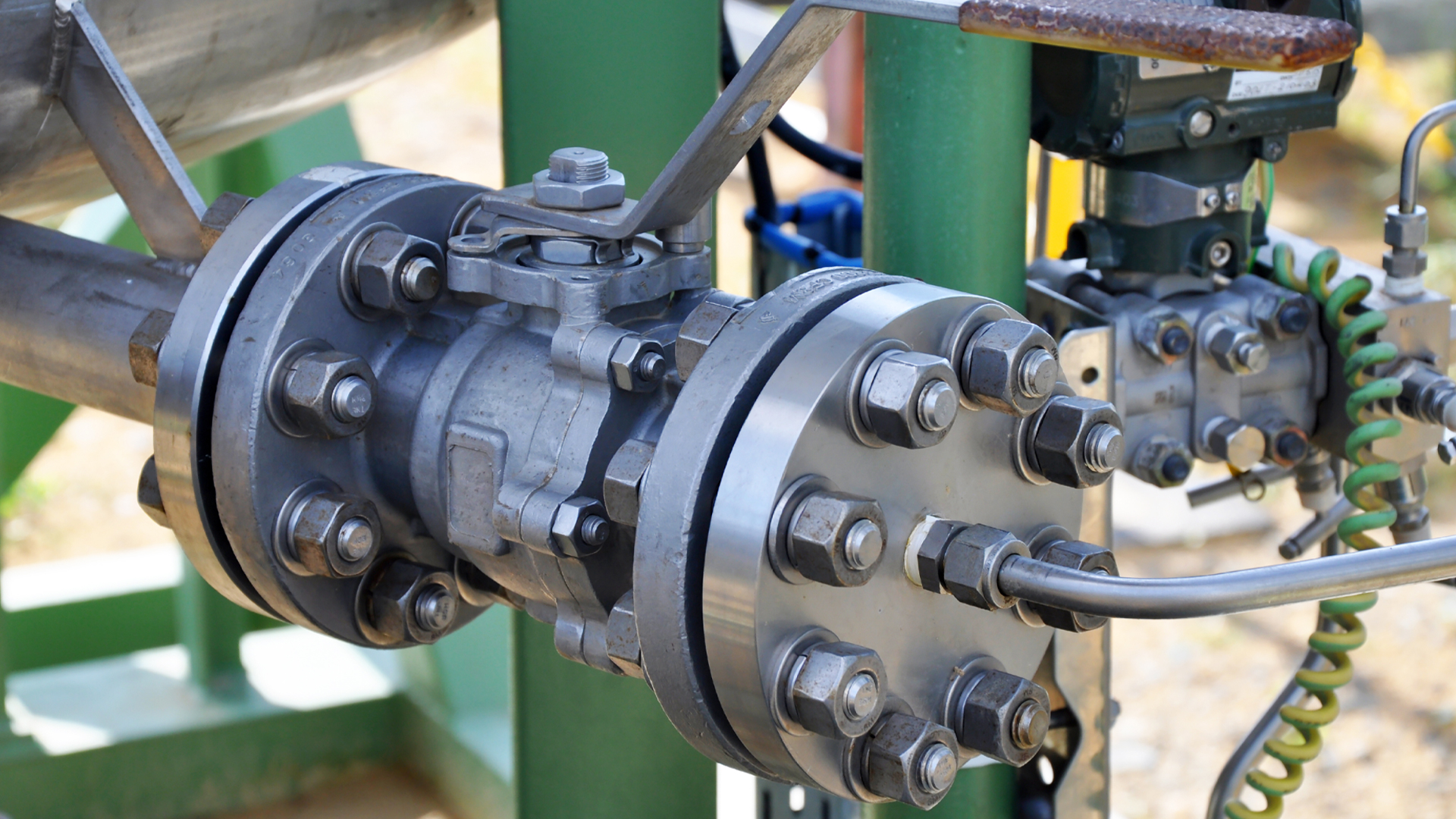

Ball valves are central to managing fluid flow in varied setups, from home water lines to complex industry tasks. These valves are known for their ease and quick action, with a quarter-turn feature for rapid opening and closing. At the core of a ball valve is a round ball device, which, when lined up with the pipes, lets flow through and, when turned, stops it.

As you start picking a ball valve, you will see various options. Full port ball valves, designed to match the pipe’s width, offer free flow and reduce pressure loss. Conversely, reduced port valves have a tinier channel, leading to more pressure loss. For more intricate setups that need to split flow in several ways, multi-port valves, like three-way and four-way options, are key.

Choosing between manual and automated ball valves depends on your system's needs. Manual ones need a hand to change states, while automated ones with actuators follow electronic signals for distant and programmed control.

As you ponder the various ball valve types, remember that the material they are made from is just as important. The next part of this guide will zero in on the material choice, ensuring your picked ball valve fits and goes beyond your application's needs.

Material Selection for Ball Valves

Material choice is crucial for the endurance and fit of ball valves with the fluids they manage. The right pick must meet your application’s unique conditions, like high heat or harsh liquids.

Considering your material options for ball valves, here is what to keep in mind:

- Brass is a common pick, noted for its lasting nature and cost-worth, fitting for setups with gentler fluids.

- The material you settle on will directly affect the valve’s life span and upkeep costs.

- A valve from a mismatched material will need more upkeep and may not last as long, raising costs over time.

With these material factors in mind, the next step is to ensure you pick the right valve size and measurements for your system's flow needs. This ensures efficient operation without unneeded pressure drops or flow limits.

Determining the Correct Valve Size and Dimension

The right ball valve size and measurement are instrumental for your system's output. To dodge common sizing errors, look at these vital factors:

- The valve size must match the pipe size and be apt for your system's flow rate.

- A too big valve for the needed flow rate can cause pressure loss in the system.

- A too small valve can limit flow and up pressure, possibly harming the system.

By focusing on these sizing details, you are preparing for an efficient and upkeep friendly system, which brings us to the next crucial point assessing ball valve function and maintenance.

Evaluating Ball Valve Performance and Maintenance

Choosing a ball valve for industry use means considering expected function in varied settings. Ball valves are known for their lasting nature and their ability to manage a wide range of fluids and gases in different industry settings.

A ball valve's function is also tied to its upkeep needs. Generally, ball valves are low maintenance. This is thanks to their simple build, which has fewer moving parts than other valve types. The material grade of the ball valve is big in deciding the upkeep routine and overall lifespan. High-grade materials like stainless steel or brass can take on tough conditions and need less frequent upkeep, thus lowering long-term costs.

As you set your function expectations, remember that your ball valve operation is influenced by pressure and heat. Hence, choosing a ball valve to manage your system's specific pressure and temperature ranges is crucial to prevent early failure or safety risks.

Pressure and Temperature Considerations for Ball Valves

Picking a ball valve for industry use means understanding the pressure and temperature ranges it will face. The valve’s ability to withstand these conditions is key for safety and adds to its durability and lifespan.

Materials are vital when ball valves face extreme temperatures. For high heat uses, materials like stainless steel or brass are suggested for their heat and corrosion resistance. Consider materials like titanium for cold uses, which can take on temperature changes without hurting the valve's integrity.

Seal function is also affected by temperature shifts. High heat can make rubber seals harden and crack, while materials like Teflon® keep their sealing traits even under such conditions.

Certifications and Safety Standards for Ball Valves

Picking a ball valve means checking certifications and safety standards to ensure your fluid control systems' safety and reliability. Look for valves that have cleared key tests, like air and hydro, to prove they can keep a tight seal and manage working pressure.

Sticking to industry safety rules is necessary, especially in high-pressure or risky settings. It is important to choose valves from makers known for their safety commitment. While approvals are key, the right actuator is also big in the valve function and fits into your system, offering a reliable and efficient fluid control answer.

Selecting the Appropriate Actuator for Ball Valves

When tasked with ensuring the efficient function of ball valves in your industry systems, the actuator you choose is critical. These devices automate the valve's movement, allowing precise fluid flow control within your system. The right actuator type is essential, as it directly impacts the valve's function, reliability, and lifespan.

Pneumatic actuators run on compressed air and are known for their dependability and cost worth. They are especially right for settings where electric power may not be on hand or could be a safety issue. Electric actuators offer precise control and are ideal for uses that need exact flow regulation. They are commonly used in systems where electricity is the main power source.

When picking an actuator, look at the power source on hand and the torque needs of the ball valve. The actuator must offer enough torque to run the valve in all conditions. Response time, fail-safe traits, and fit with control systems are also key factors.

Your ball valve system, with the right actuator, will be set to meet your industrial demands, ensuring reliable function and easy upkeep.

Also Read: Exploring the Critical Role of Materials in Ball Valve Construction

Ball Valve Installation, Maintenance, and Repair Guide

When installing a ball valve, it is key to do it right to avoid future issues. For your ball valve’s longevity and reliability, follow these key installation and upkeep steps:

- Right alignment with the flow direction is key.

- Do leak tests to make sure all connections are tight and show no signs of leaks.

- Regular upkeep means periodic checks for wear or damage.

Following these tips will help keep the valves functioning, but it is also important to think about the financial part of your ball valve investment.

Comparing Ball Valve Prices and Value

When investing in ball valves, compare prices from different suppliers. Look past the first cost and consider the valve’s build, pressure, temperature ratings, and approvals. These factors add to the valve’s overall value. A higher initial cost can lead to upkeep and function savings over time, ensuring your system works at its best.

Elevating Your Industrial Systems with the Right Ball Valve Selection

Choosing a valve that fits your application’s complexities means that safety and function are not just promised but given. The right choice now leads to fewer issues and upkeep problems later. With your smart pick, your systems will show the excellence you strive for. Reach out to your valve supplier in Russia to boost your industrial setup with a ball valve choice that stands for reliability and efficiency.