If you are looking for ways to optimise your valve systems without breaking the bank, it's essential to pay attention to the valve seat ring materials you choose. The proper selection can help your systems run efficiently and reduce overall costs.

Dive into the world of seat rings with us. Discover how to pick ones that deliver stellar performance and extend your valve systems life, without breaking the bank.

Understanding Types of Valve Seat Rings

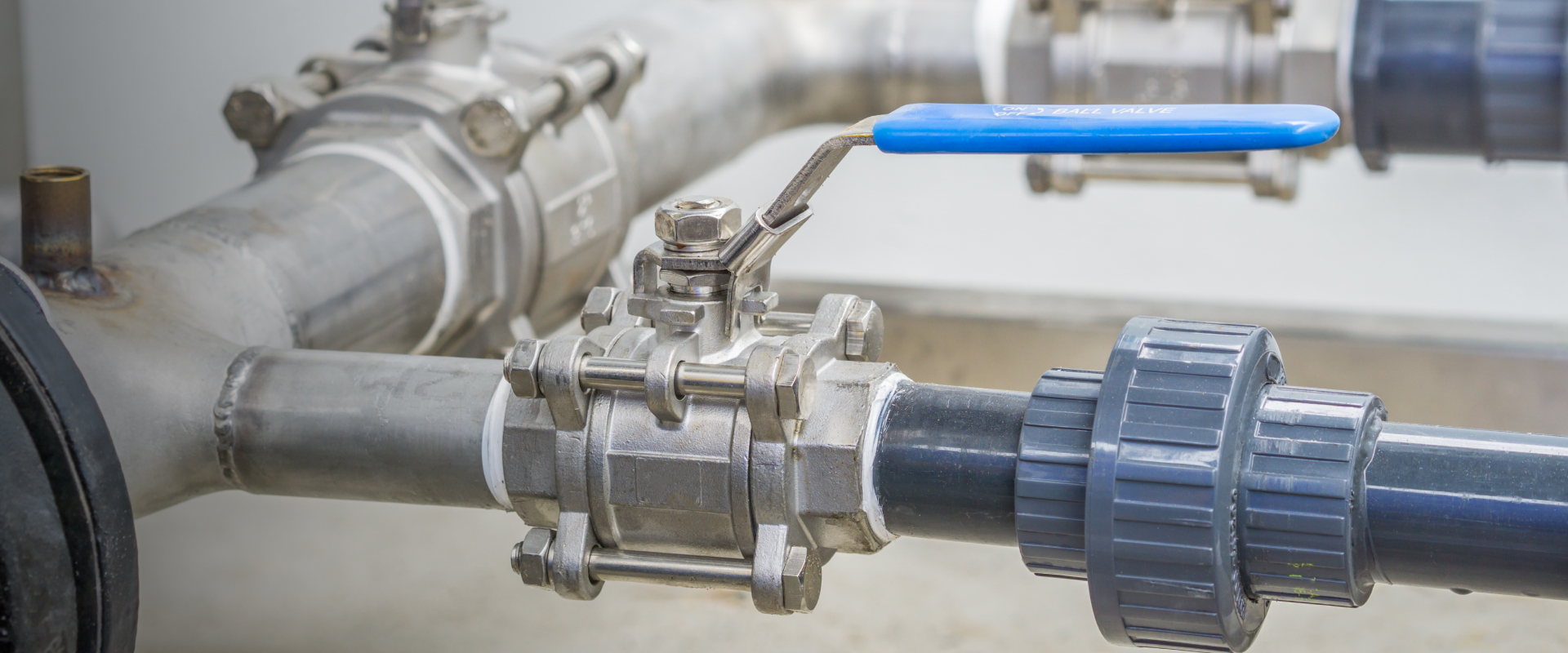

Imagine critical support for your valve plug or disc that seals the deal in your combustion chamber. That is what valve seat rings do. They are heroes in preventing leaks and upholding system integrity. Your selection here is pivotal. They are the unsung heroes preventing valves from sinking into softer materials. Think of them as the seal that locks in the valve plug or disc position.

Picking the suitable material for these rings can make or break your valve system. It is about matching the material to your operations demands for top valve action and endurance.

From steel to chrome alloys, your choice shapes your valve's destiny. So, what is it going to be? Let us navigate the options together.

Choosing Materials for Different Types of Seat Rings

What are the most ideal materials for valve seat rings? Let us decode the materials and match them to your environment.

Rubber Materials for Valve Seat Rings- Properties and Uses

Rubber gives you multiple options such as:

- Ethylene Propylene Diene Monomer or EPDM: Great for acid and base applications, but not for petroleum oils. It is also ideal for ketone and alcohol applications but not the best for aeroplane-related uses.

- HYPALON®: Oxidation, ozone, and flames do not affect Hypalon. It can withstand oxidizing acids and is a hero in the food industry.

- NEOPRENE: This versatile polymer is known for its solid resilience and oil resistance. It is predominantly used for valves in the pulp and paper industry.

Rubbers like EPDM and NEOPRENE do the trick in milder climates, but the search for tougher materials is on.

AlterValve secures high-quality industrial valves and parts from leading manufacturers worldwide, designed to meet the requirements of various sectors such as power plants, oil and gas, and petrochemicals in China, India, and Russia. Our steadfast commitment to quality and safety guarantees that our products adhere to the highest standards, delivering reliable performance across industries.

Thermoplastic Valve Seat Rings for High-Performance Materials

Carbon-filled Tetra Fluoro Ethylene (TFE) and Polyether Ether Ketone or PEEK are highly preferred for their performance in challenging environments.

- Carbon-filled TFE: When combined with graphite, carbon-filled TFE becomes extra tough. It also works well in steam applications.

- PEEK: This semi-rigid material is known for its high temperature and corrosive media.

These materials are up for the high-stakes temperature and pressure applications. But remember, even these tough materials have their limits.

Metal Options for Industrial Valve Seat Rings

For metal options, Poly Tetra Fluoroethylene or PTFE could be your star player. It can handle hot and cold extremes, making it versatile for various industrial scenarios.

Industry experts recommend PTFE for its wide temperature range and chemical resilience.

To witness these materials in action, you need a proper setup. Let’s decode these details.

Also Read: Innovations in Ball Valve Seats- A Technical Insight

Valve Seat Rings - Installation and Performance Considerations

Choosing your valve seat rings is just part of the game. Getting them installed correctly is key to keeping your valves in winning form. Follow the proper instructions to avoid damaging your valve seats and causing leaks or early valve retirement.

Analyze what your valves are up against, like heat, pressure, and the media. Make the smart call on materials that can take the heat and pressure, and you are set for smooth operations.

Heat and Pressure Resistance in Valve Seat Rings

Carbon-filled TFE and PEEK are the front runners for heat-resistant seat rings, ready to handle all kinds of thermal challenges. They are the go-to for valves that must withstand temperature and pressure extremes.

Corrosion and Wear Resistance of Valve Seat Rings

Valve durability is a must-have attribute. When considering durability, it's essential to include corrosion and wear resistance. These two attributes determine the longevity of your valve and reflect the quality and value of your purchase.

Consider a high-temperature steel cast with a chrome coating or carbon-filled TFE that can withstand high temperatures. They resist harsh environments and maintain their durability over a wide range of temperatures. PEEK is another option that retains its strength even in hot water and steam.

These materials resist corrosive media and wear, making them top picks for your valve seat needs.

Valve Seat Rings - Balancing Cost and Quality

Balancing cost and quality when investing in valves could be a tricky situation, but finding the perfect balance is important. The material you choose can greatly impact the performance of the product, as well as the impact on your wallet.

Metal seats like PTFE may have a higher upfront tag but can withstand extreme conditions, which could mean less frequent replacements. As you weigh your options, remember to consider the long haul. Resistance to wear and corrosion, plus the unique needs of your operation, should guide your choice. This way, you secure not just cost savings but also quality and lasting performance.

Final Thoughts

Feeling overwhelmed by the sea of valve seat ring choices? Your decisions here are critical for your valve system's success. From everyday rubber and plastic to the mighty metal PTFE, your selection shapes both performance and cost.

To choose wisely and dodge unnecessary expenses, get insights from your industrial valve suppliers. Your smart investment will pay off for years to come.