Ever wondered how you can keep check valves from leaking and causing havoc in your system? This guide will equip you with the know-how to detect, dodge, and deal with leaks. These skills will help you prevent problems from arising in the first place, saving you time and money.

Understanding Check Valve Leaks - Functionality and Importance

Check valves are like one-way gates for fluids, ensuring everything flows in the right direction. They work independently, popping open when the fluid pressures just right. But when that pressure drops, they snap shut to stop any backflow.

Check valve suppliers say it is crucial to have a good understanding of check valves, especially if you work in an industry where safety and efficiency are top priorities. Picking the right valve is also critical. A bad fit can lead to inefficiency or dangerous mishaps. The stakes are high with check valve problems. So, let us dive into what can go wrong and how to avoid these issues.

AlterValve sources top-tier industrial valves and parts from global leaders, customized for various sectors like power plants, oil and gas, and petrochemicals across China, India, and Russia. Our steadfast dedication to quality and safety ensures that our products maintain superior standards, delivering dependable performance across industries.

Identifying Common Check Valve Leak Issues

Check valve leaks can be difficult to detect. It can occur due to

- Wrongly installed valves

- Debris blockage

- Manufacturing defects

Understanding these causes puts you on the front lines of defence. Keeping valves installed correctly and in good shape is your best bet for stopping trouble before it starts. Here is a list of the most common leaks in check valves

Shut off Failure

When a check valve does not close all the way, you have a shut-off failure on your hands. This can cause backflow of debris, which can contaminate the entire media. This issue can occur due to a worn-out valve gasket or blocked debris.

Leakage While Closing

If your check valve fails to shut tightly, it can lead to leakage, which could be problematic for your system. This issue may arise due to:

- Worn-out parts like washers

- Presence of debris

- Improper valve installation.

To dodge these problems, clear out the debris, change the old parts, and install the valve as per the maker's guide.

Seat Seal Leaks

The seal on your valve seat is crucial to preventing leaks. A poorly positioned or aged seal can result in leaks. Fixing a leaky seal might mean putting it back in the right way or replacing it with a new one. Also, a little grease can help keep it working for a long time.

Check Valves Stem Leaks

Leakages around the stem happen when the stem wears down when it moves around. Moreover, improper alignment can also result in stem leakages.

To fix the issue, replacing damaged parts and conducting regular checks to identify signs of wear and tear early on is important. If the leakage is from the packing around the stem, following the manufacturer's guidelines should resolve the problem.

Also Read: Essential Factors in Selecting Industrial Valves

Preventive Measures to Avoid Check Valve Leaks

Keeping your valves leak-free is all about staying ahead of the game. Here are some steps to help you keep your checks valves leakage-free

- Pick the Right Valve - Choosing a valve that fits your system needs is step one to stopping leaks.

- Keep Up with Maintenance - Regularly checking for wear or damage is super important. Duly replace any worn-out parts.

- Install It Right - Make sure your valves are set up just like they should be. It must align with the pipes, and the flow needs to match the valve's design.

- Clean Up - Remove any dirt, grease, or debris from the valve to ensure it works properly.

Selecting the Right Type to Avoid Check Valve Leaks

Picking the right check valve is a big part of keeping your system leak-free. You must know your valves to stop leakages and keep things efficient. Valves are graded by how much they can leak, from Class I to Class VI. And do not forget to check the pressure capacity. Check valves work independently, so they need the right pressure to do their job.

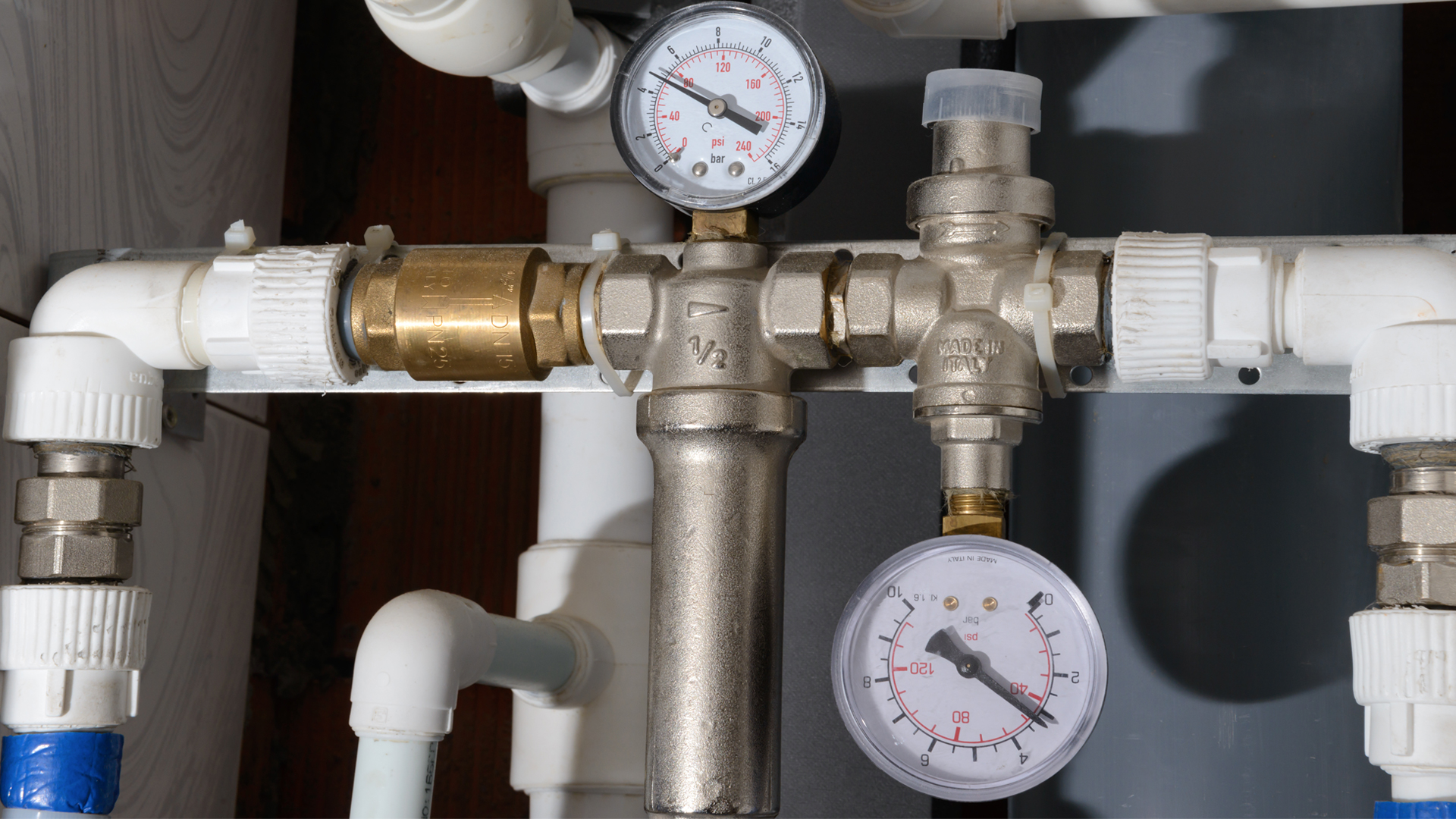

Inspection Techniques to Identify Check Valve Leaks

Spotting leaks in valves is crucial. Here is how you can spot them

- Visual Checks - Take a good look at the valve. Keep an eye out for signs like wet spots or rust.

- Feeling Around - After you have looked it over, use a cloth to check for any dampness.

- Listening - Listen closely to the valve for odd sounds that may indicate a leak.

- Bubble Test - For valves dealing with gases, try the soap solution test. Bubbles indicate a gas leak.

How to Fix Leaking Check Valves- Repair Strategies

While you can replace an old and worn-out valve, replacing some damaged components and retaining the other parts is also okay.

Here is how to handle common leak problems

- Take the valve apart and look at everything inside.

- Check the disc, seat, and spring for damage, dirt, or corrosion.

- Figure out the reasons. It could be a bad seal or a bent valve.

- Replace any worn-out parts, seals, and rings.

- Put the valve back together and hook it back up.

- Test it out by slowly bringing the pressure back.

If the leakage continues, you may have to replace the entire valve.

Check Valve Maintenance and Storage Best Practices

Taking care of your valves is key to making them last. Here are some tips to keep them in great shape

- Clean and Check - Keep your valves clean and give them a once-over regularly. When working on one, use a brush to clean the insides and eliminate any dirt accumulation.

- Lubrication Matters - Grease up the moving parts often to reduce wear. Ensure that you use the right kind of grease for your valve.

- Store Them Right - Keep your valves in a dry, airy spot. Cover the ends to keep dirt out. Keep the storage conditions just right to avoid any damage.

Final Thoughts

As you put these tips and techniques to work, remember that avoiding leaks is all about keeping a sharp eye and acting fast when you spot a problem. Got more questions or need a hand with your valves? Reach out to reputed industrial valve suppliers for professional advice.