Does your industry rely on ball valves? Did you know there are various types of ball valves for various applications?

Each ball valve type boasts unique traits to meet diverse operational needs, whether regulating flow with precision or withstanding high pressures.

This blog decodes the nuances of ball valves, their components, applications, and the elements that shape their performance. These inputs from the leading ball valve supplier will guide you to optimal choices for top-notch functionality and safety in your company’s wide-ranging applications.

Types of Ball Valves and Their Significance

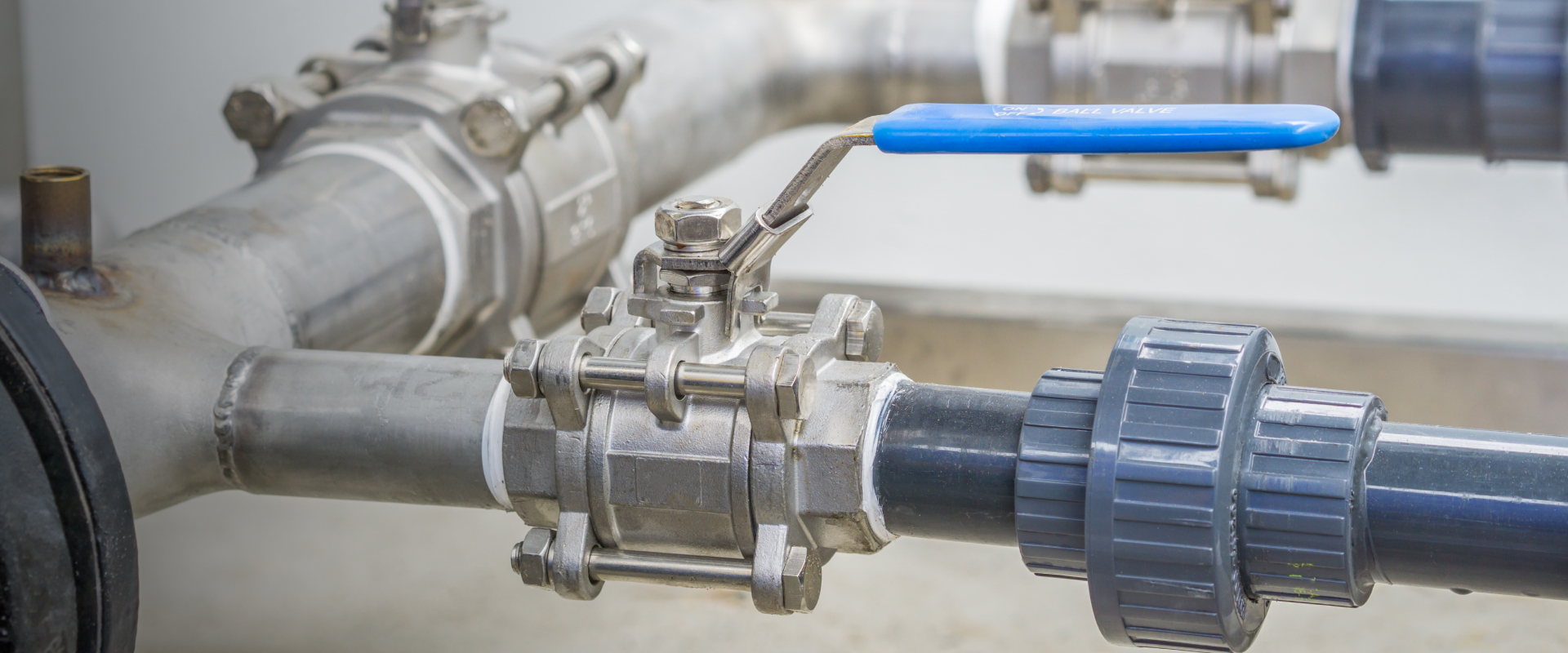

Imagine having the power to control the flow of liquids and gases with just a quarter turn. That is what ball valves do in industrial settings.

Picture a rotating ball with a central hole. Turn it one way, and fluids flow. Turn it another, and they halt. Choosing the right ball valve can save energy, cut maintenance costs, and keep your system safe.

The various types are designed for distinct industrial demands and settings, such as:

- Extreme pressure and temperature.

- Precise flow management

- Minimal contamination risk

With these basics, let us look closer at the parts and mechanics that make ball valves indispensable.

Exploring the Components and Mechanics of Ball Valves

Curious about the inner workings of ball valves? Let us break down the core parts:

- Body- A sturdy shell that holds everything together.

- Ball- A spherical gatekeeper of flow with a hole for passage.

- Seat- It seals the opening to prevent gas or fluid leakage when the valve is shut.

- Stem- It links the ball to the actuator, guiding its pivot.

This engineering marvel unfolds as you engage a ball valve. The actuator rotates the stem, which spins the ball, aligning the holes with the entry and exit. Turn it sideways, and the flow stops, sealed by the ball's solid sides against the seats.

Beyond its complexity, this knowledge is key to maintaining the efficiency and safety of your industrial system.

Now, you can explore how ball valves are used across different sectors.

Diverse Industrial Applications of Ball Valves

Ball valves are crucial in many industrial landscapes, such as:

- Oil and gas- Managing flow in wells, pipes, and tanks.

- Chemicals- Handling harsh and corrosive substances.

- Water- Treatment and distribution for precise control.

- Agriculture- Efficient water flow in irrigation.

- Management- For seawater, ballast systems, and fire suppression.

- Pharmaceutical, food and beverage industries- To maintain hygiene and prevent product contamination.

Given their multifaceted roles, several factors determine how ball valves perform in various settings.

Also read: The Central Role of Ball Valves in Various Industries

Key Factors Influencing Ball Valve Performance

A ball valve’s efficiency depends on:

- Valve size- Bigger valves need more muscle to turn.

- Pressure and temperature- High pressure and heat add resistance and require more effort to move the ball and stem

- Media density- The fluid’s weight also affects the force required to move the ball.

Here is a quick chart with rough torque values for different sizes:

| Valve Size | Torque Range |

|---|---|

| 1/4 – 1/2 | 5 10 Nm |

| 3/4 – 1 | 20 40 Nm |

| 1 1/4 – 2 | 60 100 Nm |

| 2 1/2 – 3 | 150 250 Nm |

| 4 – 6 | 500 800 Nm |

| 8 – 10 | 1000 2000 Nm |

| 12 – 14 | 2500 5000 Nm |

Remember, these are estimates. Always check with your valve manufacturer for exact torque details.

Knowing these factors, you can better understand the various ball valve types made for different industry needs.

AlterValve procures premium industrial valves and parts from renowned global manufacturers, tailored to suit the needs of diverse sectors including power plants, oil and gas, and petrochemicals in China, India, and Russia. With our unwavering commitment to quality and safety, our products consistently meet rigorous standards, ensuring dependable performance across all industries.

Ball Valve Types & Their Specific Roles in Industries

In India's industrial equipment scene, picking the right ball valve is a game changer. As a valve supplier, we guide you to the best types and setups for your situation. Consult a trustworthy valve supplier in India to find valves that fit your unique requirements.

Floating Ball Valves- Design and Applications

Floating ball valves are widely chosen for their straightforward design and operational ease. The ball floats, letting fluid pressure push it into a tight seal. They are cost-effective and easy to maintain, perfect for oil, chemicals, and water management. Yet, high pressures can wear them down, so weigh their pros and cons.

Trunnion Mounted Ball Valves- Features and Uses

Need a valve for high-pressure situations? Trunnion-mounted ball valves have a supported ball for stability and a sure seal, even under stress. They are perfect for industries where precise flow control is critical. Used in gas plants, refineries, and petrochemical sites, they handle large flows and pressures with ease. When it is about withstanding tough conditions, these valves are a standout choice.

V-Port Ball Valves Precision Flow Control

For pinpoint accuracy in your systems, V-port ball valves are the way to go. Their V-notch allows for precise flow adjustments, which is ideal for chemical and petrochemical industries and high-speed fluid oil and gas tasks. They keep the flow steady under different pressures, fitting for water treatment and HVAC systems.

Cavity-Filled Ball Valves Preventing Fluid Entrapment

Cavity-filled ball valves combating fluid traps are vital in sectors where cleanliness is non-negotiable. Filling the gap between the ball and body with PTFE, they avert fluid retention, suiting food, pharma, and chemical applications. Their design extends valve life and ensures steady operation.

Material Selection for Ball Valve Durability & Performance

The strength and performance of ball valves depend on their make. Here is a brief on common materials:

- PVC- Corrosion-resistant and flexible. It is perfect for lighter tasks.

- Bronze and Brass- Combat corrosion and are great for water systems.

- Stainless steel- Tough and extreme. Suitable for challenging jobs.

- CPVC- Handles heat well, reliable for hot fluids.

- Iron- Strong for various pressures but more prone to rust and corrosion.

Consider cost, performance, and environmental requirements to ensure your valve works well in your industrial setup.

Forging Ahead with Informed Valve Selections

Armed with ball valve insights, you are ready to choose wisely for your sophisticated systems. From trunnion-mounted to V-port, your decisions affect operation and longevity.

When in doubt, always reach out to your valve supplier in India for the right guidance. Ensure your industry's excellence and precision by contacting us for the right ball valves.