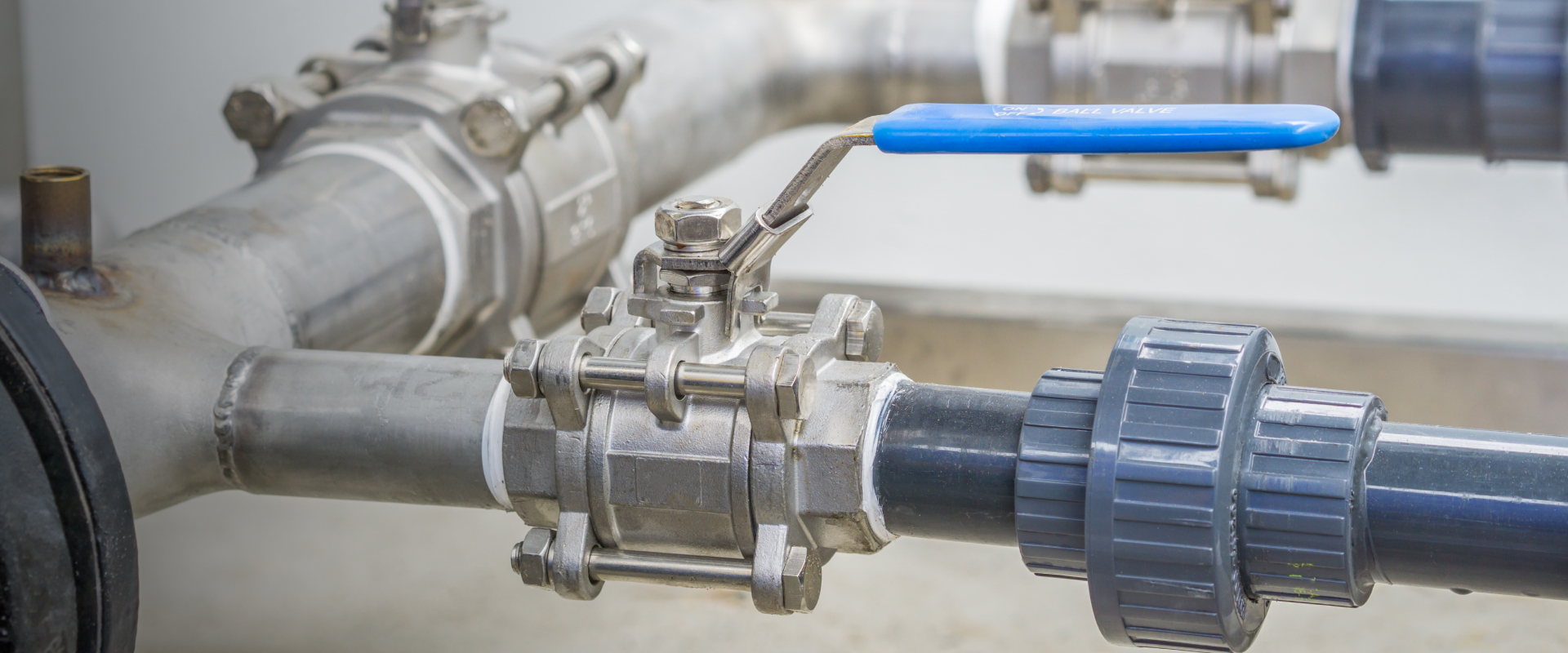

Have you ever wondered why your trusty ball valves sometimes fail and how to fix them? Ball valves are vital in managing fluid flow and are known for their durability and dependability. Yet, even the best ball valves encounter issues that affect their function.

This guide sheds light on common ball valve issues and offers practical solutions, helping you keep your systems running smoothly. Dive in to refine your skills in diagnosing and fixing ball valve challenges and maintain optimal performance.

What Causes Ball Valve Failures?

Ball valves are omnipresent in several industrial scenarios. Ball valve suppliers recommend them for their solid performance in controlling fluids for various uses.

However, no device is perfect, and knowing potential problems is critical to keeping things running well. Failures can cause downtime, safety risks, and financial loss. So, understanding the usual troubles and fixes is vital.

Why do ball valves fail sometimes?

Ball valves often regulate water and come in PVC, stainless steel, and brass. Although tough, they can wear out in 8 to 10 years. Signs of aging include leakage, overuse, and rust.

It is crucial to identify and fix issues early to prevent compromising valve quality or causing disruptions.

Knowing signs of wear helps you keep your ball valves going longer.

Common Ball Valve Issues- What You Should Look For

Here are key ball valve issues to look for during maintenance inspections:

- Internal or external leakages. Note that the internal leaks are trickier to spot.

- Clogs from dirt can slow media flow and need cleaning or actuator fixes.

- Stuck or jammed valves. This issue arises when the tool is unused for an extended period or due to sediment deposits. It can be fixed manually with the help of a bit of oil. If the issue remains unresolved, the valve must be replaced.

Keeping an eye out for these issues helps you keep your system working well.

Why Do Ball Valves Leak or Clog?

Leakages and clogs are quite common and can occur due to:

- Rough handling during installation or maintenance.

- Rust build-up on the valve.

- Sediments on the seal area.

- Wrong orientation during installation. (The valve should be kept upright.)

Clogs often come from dirt and sediment, affecting the valves functioning. Old O rings, under constant fluid push, can also cause clogs. Watch for these causes and deal with them proactively to keep your ball valves in good shape.

Corrosion and Deterioration- Hidden Ball Valve Enemies

Wear, tear, and rust can seriously hurt ball valves, leading to early failure. Rust, a natural thing, can break down vital valve parts like the seals and the ball. This wear worsens the valve’s performance and eventually leads to the replacement of the parts or the entire valve.

To tackle these issues, ensure your ball valves are well-oiled and replace old parts quickly. Regular checks help you see early signs of wear before they turn into big problems.

Now that you know the common ball valve issues, you should also know how to identify them.

Also read: The Working Principle of Ball Valves Simplified

Ball Valve Repairs- What to Do & How to Do It

If you are dealing with ball valves in your industry, knowing how to spot and fix common issues is key to keeping your work efficient.

Steps to Fix Issues

If a valve is stuck or doesn’t close right, try moving it manually. Turn off the media flow and work the valve handle to shake loose any dirt or sediment that might be the problem. If the valve is still stuck, apply oil and allow it to soak and loosen the mechanism. If these efforts do not work, you might need a new valve.

To fix leakages, look for wear, damage, or bad installation. During installation, ensure the valve is not pushed too much, which could misalign parts and cause leakage. This issue may also occur when the valve is functioning. It indicates poor maintenance or sediment accumulation on the vital components. Fortunately, regular cleaning and oiling can prevent these issues.

To prevent clogs, it is important to start with a clean installation. Ensure the valve and pipes are dirt-free before installing it. Lining things up right is just as key. Valves that are not lined up can lead to work issues and clogs. By doing these things, you will make sure your ball valves keep working well, avoiding the trouble and possible dangers of sudden failures.

Why Proper Installation and Care Matter

Perfect installation of ball valves is an evident solution to prevent several issues.

- Ensure valves are handled with care to avoid any damage.

- Ensure alignment with the existing system.

- Oil the valve adequately to prevent rust.

- Keep the seal area free to prevent clogging.

Such efforts can reduce the chances of leakages or malfunctions.

Actuators and Their Issues

Actuators are key for ball valves, especially for automatic systems. For example, electric actuators need the right voltage to work without getting too hot. Usual actuator issues include weak stems, blocks, and jammed packing, which can all come from deeper valve issues. Regular checks in manual mode can spot actuator issues early.

The key to ball valves lasting and being reliable is regular care and quick problem-solving. As you keep your valves working well, remember that staying ahead on maintenance can help stop potential issues from getting worse.

AlterValve is a valve supplier that offers a wide range of high-quality industrial valves and parts for various sectors such as power plants, oil and gas, petrochemicals, and more. It sources its products from qualified valve manufacturers and supplies in China, India, and Russia, and ensures that they meet strict quality and safety standards.

How to Fix Ball Valve Leakage & Sealing Troubles

When experiencing ball valve leakage and sealing issues, it is crucial to address them promptly to prevent system damage and minimise downtime. To fix drips and sealing issues, follow these steps:

- Tighten the valve fittings with pliers to stop the leakage.

- Replace the inner seal or the entire valve if necessary.

- If the valve is stuck or unable to close fully, you might need to switch it.

- Turn off the media supply before replacing and installing the new valve.

- After installation, check for any leakage or loose parts.

It is key to know when to replace valves and seals to dodge sudden breakdowns. Regular inspections help you know when parts are worn and need changing.

How to Stop and Handle Ball Valve Rust and Wear

To fight rust and wear in ball valves:

- Choose materials like stainless steel or brass, which stand up well to corrosive stuff.

- Conduct regular inspections to find rust so you can handle it in time.

- Use the right oil to curtail wear due to prolonged usage.

- Replace worn parts to keep your valve systems whole.

With these plans in action, your ball valves are better guarded against the effects of time and use, ensuring they perform well and reliably.

How to Extend Your Ball Valve Lifespan

Making sure your ball valves last and are reliable is not just luck. It comes from good maintenance plans. When you need new valves or parts, work with good ball valve suppliers to get parts made to last and fit well. Regular care schedules are key, letting you see and stop possible failures before they happen.

Putting money into top-notch valves and materials can make a difference in how your ball valves work and how long they last. Choosing valves designed for specific applications will also help you dodge common issues like wear and tear or misalignment with the system.

Ultimately, preventing common issues with ball valves is highly valuable. It is an investment in work well done and reliability that pays off in the long run.

Top Care for Excellent Ball Valve Performance

Consistent valve maintenance leads to better work across your operations. The tips here show how to get ahead of common ball valve issues, giving you ways to solve drips, clogs, and wear and tear.

To boost your care plan and guard against valve failure, reach out to your industrial valve suppliers. Their experienced guidance is essential to improve your ball valve performance, durability, and reliability.