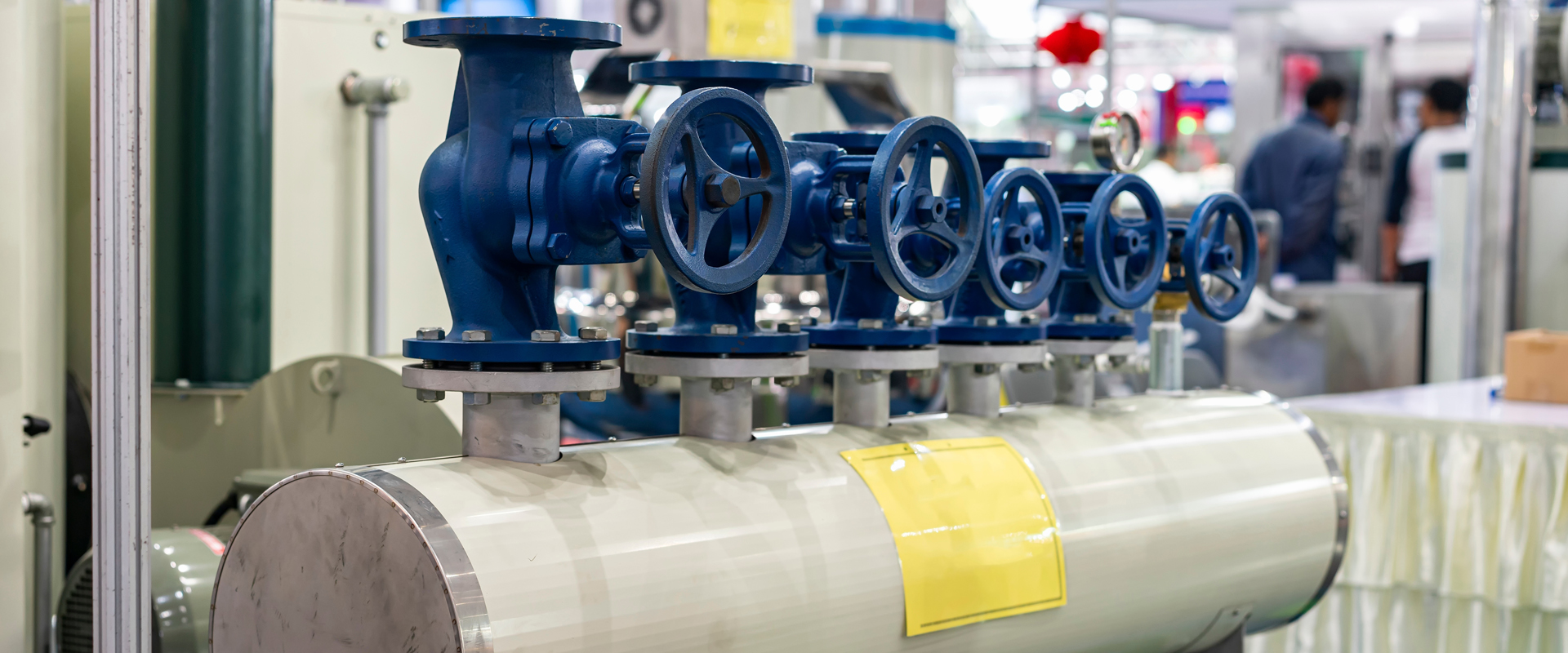

Do you know the pivotal part globe valves take in controlling fluid flow within many industrial systems? The secret to their effective operation lies in understanding the directional flow of these valves. Choosing the right globe valve for your system can sometimes be a challenge for an industrial engineer.

This article provides a thorough understanding of the different globe valve designs, and how they affect the directional flow and offers practical tips for selecting globe valves based on flow direction. So, what is the directional flow of the globe valve? Let's first understand the basics of the globe valve. For the most insightful guidance and expertise, consider seeking advice from

Understanding the Basics of Globe Valves

We will provide a comprehensive understanding of the basics of globe valves. This involves a detailed explanation of their design and components, culminating in a clear understanding of their functionality. This information is essential in comprehending the directional flow of a globe valve. Let's begin with the valve’s design and components.

Design and Parts of Globe Valves

The globe valve, known for its spherical body, employs a disc to regulate the fluid flow in a pipeline. The movement of the valve stem, which is controlled by the turning of the handwheel, impacts the valve flap. The valve flap moves towards or away from the valve seat axis, which manages the connection in your pipeline. This mechanism controls the directional flow of the globe valve.

The components of the globe valve work in harmony, making it a critical component in any fluid dynamics system. The design and function of the globe valve are intricately linked.

In the following sections, we shall discuss how a globe valve operates in a system, providing a basic understanding of the flow direction.

Functioning of Globe Valves

The directional flow of the globe valve is primarily managed by the movement of a disc or plug along an axis that stands perpendicular to the flow direction. To simplify, the globe valve works by forming a seal through a circular hole perpendicular to the pipe axis using a disc or piston. As the disc or piston rotates, it uncovers a cylindrical cavity with ports, slots, or holes. This disc or piston typically gets its drive from a shaft with the assistance of a spring. A secondary hydraulic circuit with pilot valves and differential pressure can handle the valve's opening in autonomous control. This mechanism significantly contributes to controlling the valve's position, which we will discuss next.

The position of the globe valve can:

- Stop, start, and regulate the flow of a system.

- Determine the volume of fluid flowing through the valve based on the position of the disc with the seat; the farther it is from the seat, the more fluid flows through.

A notable characteristic of globe valves is that they present a considerable amount of resistance to fluid flow even when fully open, distinguishing them from other valve types like gate valves. On the other hand, gate valves, when fully open, offer less resistance and minimal pressure decrease. Hence, they are the go-to option when minimal flow limitation is required, while globe valves are apt for precise flow control.

The globe valve stem typically executes a rotary lift motion with a handwheel attached to the top of the stem. The rotation of the handwheel impacts the valve sealing surface, resulting in the closure or opening of the shut-off valve.

Knowing how a globe valve operates and its control over flow direction is vital for its effective application in various industries. But how does the design of the globe valve affect this flow direction? We will explore this in the following section.

Also read: Choosing The Right Globe Valve: Selection Tips And Considerations

The Directional Flow of Globe Valves

The necessity to grasp the directional flow of globe valves becomes paramount, particularly when you find yourself amid high-pressure and high-temperature systems. The design of the valve is not the sole factor here; the specific requirements of your system also hold significant importance. Let's delve into this more.

Determining the Flow Direction in Globe Valves

The flow direction of a globe valve is determined by a few specific factors. These include the pressure, viscosity, and temperature of the fluid, as well as the velocity of the fluid dynamics. The valve, a critical component of the piping system, must be correctly installed to ensure optimal performance. Incorrect installation can lead to leaks, torque imbalances, and a reduction in the lift force.

The flow measurement of a globe valve is typically indicated by an arrow on the valve body. This arrow points towards the low-pressure area, indicating the direction of flow. In cryogenic applications, it is common for the shutdown valve to be installed in the reverse flow direction to prevent potential damage to the actuator.

Understanding the directional flow of the globe valve is crucial for its operation and maintenance. Therefore, regular checks and maintenance are essential to ensure the valve's longevity and efficiency.

Having understood the importance of flow direction in globe valves, let’s now understand the importance of correct flow direction.

Importance of Correct Flow Direction

Understanding the correct flow direction in a globe valve is of utmost importance. It significantly influences the closing and opening torque during valve actuation, a crucial factor in high-pressure and high-temperature systems. The correct flow direction in these systems ensures that the flow diffuses instead of concentrating on the disc's face. This diffusion process prevents the stem from contracting when it cools down.

Let's examine how this works in different system conditions. In applications with low pressure and temperature, globe valves allow the pressure to flow under the disc. This design lets the disc rotate freely on the valve stem, fitting snugly against the seat as the valve closes, thus reducing seat leakage.

However, the situation changes in high-pressure and high-temperature systems. Here, globe valves allow the pressure to flow above the seat.

Installing incorrectly against the indicated flow direction can cause immediate malfunction. This results in subpar valve performance and a shorter lifespan. Therefore, the correct flow direction is vital for optimal performance and longevity.

Now that we understand the importance of correct flow direction, it’s time to explore the different types of globe valves based on the same.

Types of Globe Valves Based on Flow Direction

In the sphere of globe valves, the directional flow holds a vital role that defines their function. There are two main types considering this factor: straight-flow and angle-flow globe valves. The design and the maintenance of flow direction in these valves are distinctive, each presenting its own benefits. So, let's focus on these valve types and comprehend their operation.

Straight-Flow Globe Valves

Straight-flow globe valves, also known as Z Type Globe Valves, are notable for their linear flow path. Their design includes vertically aligned inlet and outlet ports, a spherical body, a movable disc, a stationary seat, and a stem that connects the disc to an external handwheel or actuator.

This simple yet effective design makes straight-flow globe valves a preferred option for many applications.

The flow direction in these valves can adapt to the system's needs. Here are two typical scenarios:

- In applications with low pressure, the flow is generally "low-in and high-out." The fluid enters the valve from under the disc, which lifts it upwards and opens it. This direction requires more torque for closing and less for opening.

- For larger globe valves (8 inches or more) with a nominal pressure of 200 or more, the flow is usually "high-in and low-out". The fluid enters the valve from over the disc, causing it to close. This direction suits high-pressure and high-temperature applications well.

The flow coefficients are crucial when choosing a globe valve based on flow direction, which can significantly differ depending on the valve's bore pattern. For instance, the Z-shaped or T Pattern positions the valve seat horizontally, allowing the stem and disc to move at right angles to the pipe axis. This results in good throttling and sealing ability. However, it also results in low flow coefficients as the pressure drop across the valve is high. This happens because the flow must make two 90° turns between the valve inlet and outlet, creating a “Z” shape.

After discussing the design and flow direction of straight-flow globe valves, we will discuss the specifics of angle-flow globe valves and how their unique design influences the flow direction.

Angle-Flow Globe Valves

The angle-flow globe valves, one of the different types of globe valves, are notable for their unique design. The design of these valves has the inlet and outlet ports at a 90-degree angle to each other. This design effectively changes the fluid's flow direction and is especially beneficial in environments with limited space.

Let's look at the main components of an angle-flow globe valve:

- Body

- Disc

- Seat

- Stem

In reality, an angle-type globe valve is a modified version of traditional globe valves. The design includes right-angled intake and exit ports, which help to decrease pressure drop when fitted at pipe bends. This design allows the diaphragm to move at right angles to the pipe axis, thus improving efficiency by only needing one elbow instead of two.

This ensures that the valves are designed to perform optimally under high-pressure conditions. The angle pattern of these valves allows them to function both as a valve and a 90° elbow. This results in a lower pressure drop and higher efficiency compared to the Z-shaped globe valve.

Having understood the design and function of angle-flow globe valves, we will discuss how these valves determine the directional flow in the following section.

AlterValve procures premium industrial valves and parts from renowned global manufacturers, tailored to suit the needs of diverse sectors including power plants, oil and gas, and petrochemicals in China, India, and Russia. With our unwavering commitment to quality and safety, our products consistently meet rigorous standards, ensuring dependable performance across all industries.

Considerations for Selecting Globe Valves Based on Flow Direction

Choosing the appropriate globe valve, considering the flow direction, might seem complicated. It involves more than just comprehending the flow direction. It also requires you to consider multiple factors and steer clear of frequent errors. The forthcoming sections will serve as a guide, assisting you in making knowledgeable choices when it comes to globe valves.

Explore our blog titled "Choosing The Right Globe Valve: Selection Tips And Considerations" to gain additional knowledge and insights on selecting the ideal globe valve for your industry needs.

Factors to Consider

When you choose the right globe valve for your system, understanding its directional flow becomes crucial. The design of the valve and the flow characteristics inherent to it, shaped by the disc or plug head, determine this. Globe valves can show linear, equal percentage, or quick opening flow characteristics.

Depending on your system's requirements, you might need to consider various types of globe valves. Here are some considerations:

- For systems working under high temperatures and pressures, like in thermal power stations, nuclear power plants, or petrochemical systems, disconnecting valves is recommended. These valves handle such conditions effectively and don't require strict flow resistance on the pipeline, so pressure loss is not a major concern.

- For systems working under low temperatures and pressures, a globe valve with a unique design is necessary. A standard globe valve will handle pressure flows under the seat. However, a globe valve that allows pressure to flow above the disc is the better choice for more challenging conditions.

As we progress, we will discuss some common mistakes to avoid when choosing a globe valve, ensuring your system operates optimally.

Common Mistakes to Avoid

Choosing a globe valve based on the correct flow direction is vital for its optimal performance and longevity. However, there are certain common mistakes you should avoid.

- Disregarding the manufacturer's indication of flow direction: This could cause malfunctions.

- Installing the valve incorrectly: This could compromise its performance and shorten its lifespan. For example, in straight pattern globe valves, you should install the stem vertically to prevent sediment from accumulating.

By understanding these common mistakes, you can make a well-informed decision when choosing globe valves based on flow direction.

Final Thoughts

This guide simplifies the complexities of globe valves and their directional flow. It's important to remember that the design and operation of these valves play a crucial role in determining their flow direction. Get the most insightful guidance and advice from AlterValve, the best globe valve supplier in India.

Globe valves come in various designs, each having a unique flow direction. When selecting a globe valve, considering the flow direction requirements of your system is crucial to avoid common mistakes. For further insights or any assistance, our experts at AlterValve, the leading valve supplier in India, are always willing to help. Understanding the flow direction in globe valves is not just a piece of information for an industrial engineer but a fundamental requirement.