What is a gate valve’s mechanism and working? This is a frequent question among engineers and technicians. But don't worry! This article aims to simplify the mechanism and workings of a gate valve for you. It provides a comprehensive explanation, covering everything from the essential components to the detailed operation procedure. You will also get to understand the diverse industrial uses of gate valves from AlterValve, the experienced gate valve supplier in India. Are you ready to acquire this valuable knowledge? Let's start!

Understanding Gate Valves: Definition and Function

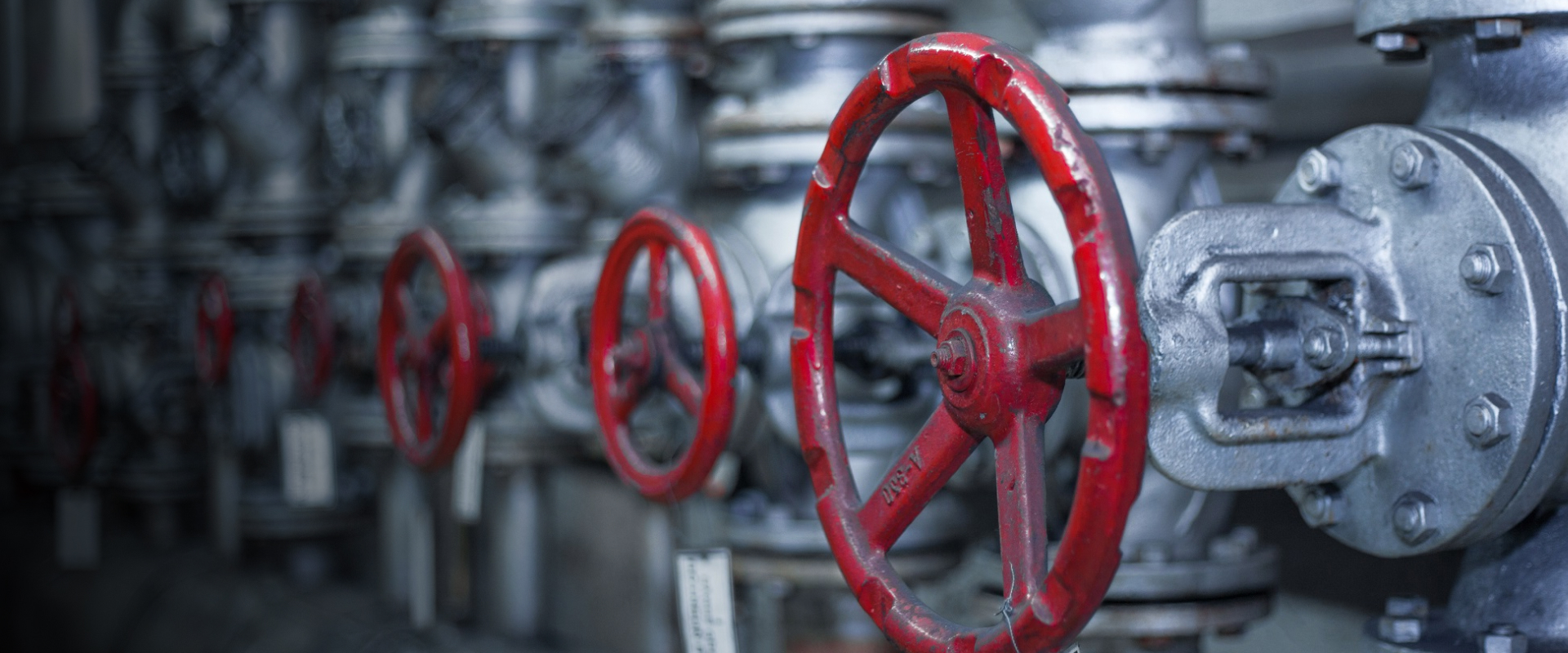

When we examine gate valve mechanics, we must recognise its components. Each part contributes to the valve's overall function. Understanding this is crucial to grasping how a gate valve works. Now, we can examine the different components of a gate valve.

Components of a Gate Valve

There are seven key parts, namely:

- The Body: It matches the pipe system's measurements, typically having flanged ends.

- The Stem: It threads to the actuator or the gate, playing a vital role in operating the valve.

- The Packing: This material forms a vacuum between the stem threading and the main body, improving the valve's performance.

- The Bonnet: Positioned above the main body, it houses the stem thread.

- The Gate: It resembles a wedge and serves as the valve's barrier.

- The Seats: They provide a firm base for the gate valve.

- The Actuator: It is a significant component that triggers the valve.

Other crucial parts include the handwheel, which turns the stem, which in turn moves the gate up or down through the threads. This movement manages the flow within the valve. The spindle, gasket, and flange also significantly contribute to the valve's operation.

Having familiarised yourself with the parts, it is time to comprehend how these components collaborate to control fluid flow. Are you ready to learn about this in the next section?

Mechanism of a Gate Valve

This section will guide you through the gate valve's operation and provide a comprehensive explanation of how it works. As you proceed, you'll better understand how this vital device operates within your system. Let's proceed and acquire more knowledge about this significant topic.

Operation of a Gate Valve

A gate valve primarily performs two actions: opening and closing. Here's the process:

- For opening the valve, twisting the handwheel is necessary. This movement elevates the gate along the stem, creating a clear path from the inlet to the outlet for fluid flow. Note, that this action isn't immediate; it demands more than a full rotation.

- For closing the valve, the handwheel needs a rotation in the reverse direction. This action descends the gate along the stem, stopping the fluid flow. This action also demands more than a complete rotation.

It's crucial to understand that the vertical movement of the gate and the flow rate don't share a direct relationship. The most significant changes surface when the valve is nearly closed. When the valve is partially open, the high flow velocity can cause wear on the gate and seat. This wear could reduce the valve's lifespan due to vibrations in the gate.

So, your understanding will surely be enhanced when you come across a gate valve in your industry next time. Now, with a better understanding of a gate valve's operation, you're better prepared to handle them. Hence, let's move on to the applications of gate valves in various industries.

Also read: How to Choose the Right Gate Valve: Technical Specs for the Right Choice

Applications of Gate Valves in Industry

Gate valves are crucial in industries that need precise control over fluid flow. Their shut-off mechanism allows or stops the flow of liquids and gases through a pipe or pipeline system, making them an essential component in many sectors.

Here are some of the diverse industries that depend on gate valves:

- The Petroleum Sector: Oil and gas pipelines, petrochemical facilities, refineries, and gas processing plants regularly use gate valves. They handle moderate pressure but high temperatures.

- Water and Waste Management: Water and wastewater treatment plants often use these valves.

- Power Generation: Power plants and utilities frequently use gate valves.

- Processing Industries: Industries from chemical processing to food processing heavily depend on gate valves.

- Other Industries: Mining and refining operations, the pharmaceutical industry, the automotive industry, the shipping industry, and the marine industry all use gate valves.

Due to their adaptability, gate valves have applications beyond these traditional sectors. They're not just limited to these industries. They also effectively handle slurries and viscous liquids such as heavy oils, light grease, varnish, molasses, honey, cream, and other non-flammable liquids. But they're not suitable for sanitary conditions. They're perfect for situations that need a shut-off valve. To delve deeper into the industrial applications of gate valves, we invite you to peruse our comprehensive article, "Applications of Gate Valves."

The versatility of gate valves also reaches food services, pharmaceutical services, feedwater applications, steam applications, and powder product applications. They can manage a wide variety of liquids, including:

- Steam

- Water

- Oil

- Air

- Gas

With such a broad range of uses, it's important to consider the financial implications of using gate valves.

Cost-Benefit Analysis of Using Gate Valves

Are you thinking about using gate valves for your project? Understanding the financial aspects is essential. This includes the costs associated with these valves, from purchase to maintenance. But there's more. You'll also learn about the benefits and potential savings that they offer. This cost-benefit analysis will help you make a well-informed decision.

Costs Associated with Gate Valves

Understanding the costs associated with gate valves in your industry is as crucial as understanding their mechanism and operation. Let's review these costs.

- Purchase cost: A gate valve's price depends on its type, size, and material.

- Installation cost: This includes the valve, necessary tools and materials, and labour cost. The location and any additional charges can also influence the overall cost.

- Maintenance cost: Regular upkeep ensures your gate valves' longevity and proper working. The cost for this depends on the valve's condition and the maintenance procedures' complexity.

- Replacement cost: If a gate valve fails or gets stuck, you'll need to replace it at the cost of a new one.

- Total cost of ownership: This includes the initial installation cost and potential future expenses. For instance, low-cost, poor-quality valves may fail early, leading to additional labour and equipment costs for excavation, de-installation, and repair. You may also need to consider the cost of replacement materials and damage to the surrounding infrastructure from water damage or erosion.

Considering these costs will help you make an informed decision. But don't stop here. Understanding the benefits and potential savings can also assist in making a well-rounded decision.

Benefits and Savings from Using Gate Valves

While people often discuss the costs of gate valves, we should equally stress their benefits and potential savings.

The body of the gate valve has a straight-through design, a feature that allows fluid to flow with minimal resistance when the valve is fully open. This design provides better sealing performance than shut-off valves, and the mechanisms for opening and closing are quicker and more user-friendly. They also offer versatility. Gate valves work well as venting and low vacuum system valves due to their wide application range.

Their bidirectional nature means they are not limited to one-way flow, making them ideal for pipelines where the flow direction might change. This straightforward installation distinguishes them from other more complex types of valves.

Gate valves show a relatively low-pressure drop when in use and can close in either direction. They are built to withstand high pressures and temperatures and need less maintenance. These features can lead to potential savings, as outlined below:

- Decrease in maintenance costs

- Increase in efficiency

- Extension in service life

Wrapping It Up

You have explored the intricate world of gate valves, understanding their parts, their workings, and where people use them. This new understanding emphasises the crucial role that these valves play in controlling the flow of fluid in many industries. You have also discovered the cost benefits and potential savings of using gate valves.

As your professional journey unfolds, remember the importance of these versatile devices. Keep learning, stay curious, and always aim for efficiency in your work. After all, the core of engineering is the constant quest for improvement.

AlterValve, India’s foremost industrial valve supplier, can aid you in this journey. Contact our experts for professional guidance in understanding your valve mechanism.